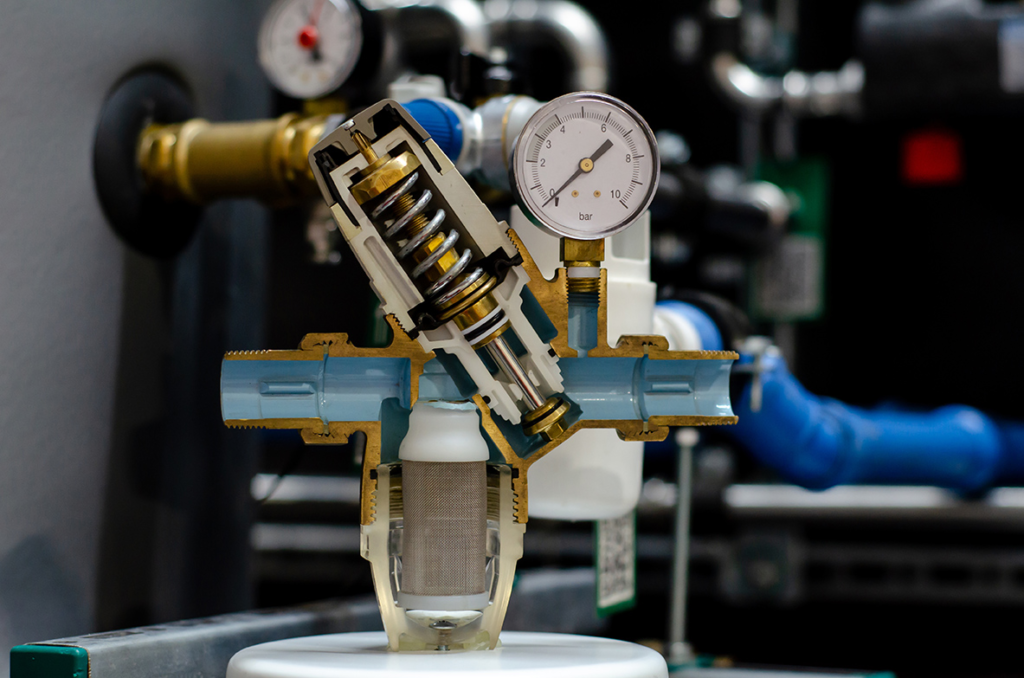

A pressure reducing valve (PRV) is a critical component in plumbing and industrial systems, designed to regulate water or gas pressure and ensure safe, efficient operation. However, when a PRV becomes faulty, it can lead to various problems that affect system performance, increase maintenance costs, and even pose safety hazards. Understanding the issues caused by a malfunctioning PRV is essential for timely detection, repair, and prevention. This article explores the common problems associated with a faulty pressure reducing valve and their impact on plumbing and industrial applications.

NOTE:- Pressure Reducing Valve was regularly inspected and maintained by Sensor Techuae, preventing leaks and prolonging system lifespan. Don’t let pressure fluctuations cause damage. Schedule your maintenance now!

Impact on Water Pressure Regulation

Excessively High Water Pressure

A defective PRV may fail to regulate pressure effectively, leading to excessively high water pressure. This can cause damage to pipes, fixtures, and appliances. High water pressure increases the risk of leaks, pipe bursts, and premature wear on plumbing components, leading to costly repairs and water wastage.

Low or Fluctuating Water Pressure

Conversely, a malfunctioning PRV may excessively restrict water flow, resulting in low or fluctuating water pressure. This can cause problems such as slow-filling appliances, weak shower performance, and inefficient water distribution in buildings. Inconsistent water pressure can also negatively impact industrial processes that require stable pressure levels.

Increased Wear and Tear on Plumbing Components

Pipe Damage and Leaks

When a PRV fails to regulate pressure effectively, pipes may experience excessive stress due to sudden pressure surges. Over time, this can lead to small cracks, joint failures, and leaks, increasing water loss and repair expenses.

Damage to Valves and Fixtures

High water pressure caused by a faulty PRV can accelerate wear on faucets, showerheads, and other fixtures. Washers, seals, and internal components may degrade more quickly, leading to frequent replacements and maintenance issues.

Negative Effects on Water Heating Systems

Increased Risk of Water Heater Damage

A faulty PRV can cause elevated water pressure within a water heater, leading to overheating, tank stress, and even explosion risks in extreme cases. High pressure can also force water into the expansion tank, causing it to malfunction and reducing the efficiency of the heating system.

Inconsistent Hot Water Supply

Fluctuating pressure due to a defective PRV may result in inconsistent hot water temperatures, making it difficult to maintain a stable water supply in residential and commercial settings. This can be particularly problematic for households relying on tankless water heaters, which require stable pressure for optimal performance.

Increased Energy Consumption and Costs

Higher Utility Bills

When a PRV fails, excessive water pressure can lead to increased water consumption, raising utility bills unnecessarily. Leaks caused by high pressure can further contribute to higher water usage and waste.

Inefficient System Performance

Water-using appliances such as dishwashers, washing machines, and irrigation systems rely on stable pressure for efficient operation. A faulty PRV can cause inefficiencies, forcing these appliances to work harder and consume more energy, leading to higher electricity and water bills.

Safety Risks Associated with a Faulty PRV

Risk of Pipe Bursts and Flooding

One of the most severe consequences of a malfunctioning PRV is the risk of pipe bursts, which can cause extensive water damage to homes, businesses, and industrial facilities. Burst pipes can lead to flooding, structural damage, and costly repairs.

Potential for Backflow Issues

A defective PRV can disrupt the balance of pressure within a plumbing system, increasing the risk of backflow. This can lead to contamination of the potable water supply, posing serious health risks to occupants.

Problems in Industrial Applications

Reduced Efficiency in Manufacturing Processes

In industrial settings, pressure reducing valves are used to regulate gas and liquid flow for various manufacturing processes. A malfunctioning PRV can disrupt production, cause inconsistencies in operations, and lead to product defects.

Increased Maintenance and Downtime

Industries relying on stable pressure regulation must frequently inspect and maintain PRVs to avoid downtime. A faulty PRV can lead to frequent equipment failures, production delays, and increased maintenance costs.

How to Identify and Address a Faulty PRV

Common Signs of a Faulty PRV

- Unusually high or low water pressure

- Noisy pipes or water hammering sounds

- Frequent leaks or dripping faucets

- Fluctuations in water temperature

- Increased water and energy bills

Steps to Fix or Replace a Faulty PRV

- Conduct a pressure test to determine irregularities

- Inspect the valve for visible damage or leaks

- Adjust the valve settings if pressure is too high or low

- Clean or replace clogged components if necessary

- Consult a professional plumber for repairs or replacements if issues persist

Conclusion

A faulty pressure reducing valve can cause a range of problems, from excessive water pressure and increased energy costs to safety hazards and industrial inefficiencies. Regular inspections and timely maintenance are crucial to ensuring optimal performance and preventing costly damages. By understanding the risks associated with a malfunctioning PRV, homeowners, businesses, and industries can take proactive steps to maintain water pressure stability and system efficiency.

For more insightful articles related to this topic, feel free to visit – techners

Leave a Reply