Construction projects rely heavily on good building materials. The quality of these parts affects the final building, especially construction materials Philippines. Contractors need to select materials that perform well under local conditions. Using the right materials is a major part of successful building.

Important Building Components

A structure needs various basic materials to stand strong. These materials include cement, steel bars, aggregates, and wood. Contractors buy these items from suppliers across the country. They form the backbone of both residential and commercial projects.

Cement and Concrete Usage

Cement is a binding agent that mixes with water and aggregates. The resulting mixture is concrete, which hardens into a very strong substance. Concrete is a popular choice for foundations, columns, and slabs. High-quality cement mixes offer better resistance to water and cracking. Contractors often look for cement brands that consistently meet quality standards.

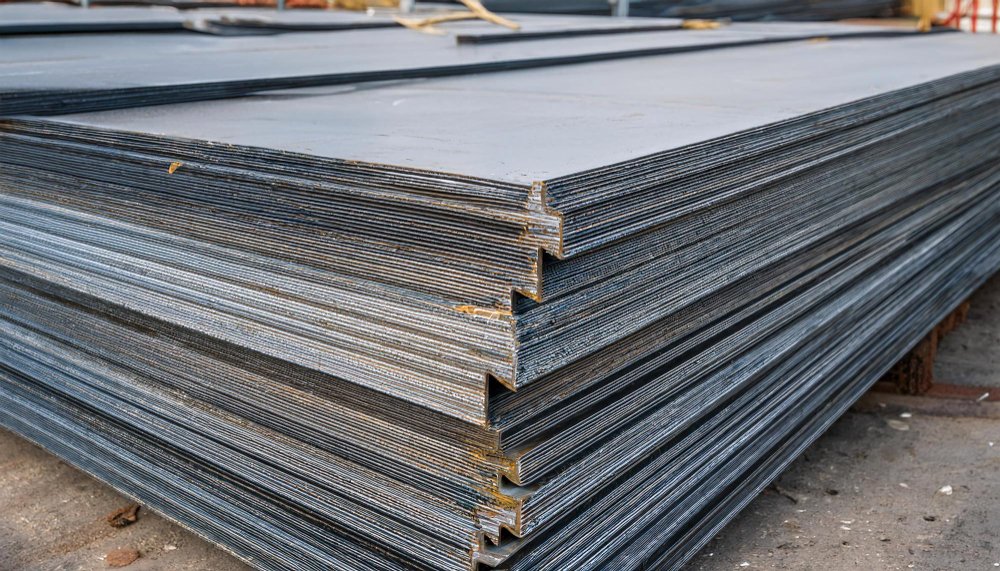

Steel Reinforcement Bars

Steel bars, or rebar, provide strength to concrete. Concrete is strong when pressed, but steel helps it resist pulling. The size and grade of the steel must match the engineering design. Using the correct steel prevents structural failure over time. The Philippines uses specific standards for measuring steel strength.

Aggregates: Sand and Gravel

Aggregates are inert granular materials like sand, gravel, and crushed stone. They make up the bulk of a concrete mixture. Clean and properly graded aggregates result in stronger concrete. Dirty or impure aggregates can make the final concrete weak. Proper sourcing of aggregates matters greatly for structural integrity.

Lumber and Timber Applications

Wood is a traditional and versatile material used in framing, roofing, and finishing. Different types of wood offer varied strengths and resistances to pests. Treated lumber lasts longer and resists termites, which is important in tropical areas. Selecting durable wood avoids early replacement or repair.

Cost vs. Quality in Material Choices

Balancing cost and quality is a constant challenge in construction. Cheaper materials may reduce upfront expenses but often lead to maintenance issues. High-quality materials typically last longer and reduce repair costs over time. Contractors must evaluate both price and performance.

Material Storage and Handling Practices

Proper storage of construction materials affects their performance. Steel should be protected from rust, cement kept dry, and wood stored off the ground. Incorrect handling can lead to damage or contamination. Good storage practices maintain material integrity until installation.

Benefits of Selecting Quality Materials

Choosing materials based only on the lowest price can lead to long-term problems. Quality building materials offer several benefits, particularly construction materials Philippines. They enhance the safety, durability, and life span of the structure. Low-quality materials often fail fast, leading to high repair costs.

Safety and Structural Integrity

Good materials meet or exceed local building codes. They are tested for strength, fire resistance, and seismic performance. Using certified materials directly improves the safety for people using the building. Structures must withstand typhoons and earthquakes common in the region.

Durability and Maintenance

High-rated materials resist wear and tear from weather and daily use. Durable finishes and coatings mean less fading or cracking. Contractors have fewer repairs to do after the project ends. Long-lasting buildings offer better value for property owners.

Project Efficiency Gains

Reliable materials are often consistent in quality and size. This consistency speeds up the construction process. For example, uniform steel bars fit together correctly without extra cutting. Fewer material defects also reduce wasted time and money on site.

Strategy for Sourcing Top-Rated Materials

Contractors use a careful approach to choose the best materials for their projects. This process involves checking certifications and comparing suppliers. They also consider the specific demands of the project location.

Checking Material Certifications

Materials should carry seals of approval from relevant government agencies. These certifications confirm the product meets national quality standards. Philippine National Standards (PNS) are a key reference for quality assurance. Never compromise on materials without proper certification.

Vetting Reliable Suppliers

A supplier’s reputation is as important as the product itself. Reliable suppliers deliver on time and store materials correctly. Contractors often build long-term relationships with trusted distributors. They give materials that are real and easy to trace back.

Considering Specific Application Needs

The materials used for a bridge differ from those used for a house. Materials for seaside construction need to resist corrosion from salt air. Interior finishes must suit the building’s function and expected traffic. Choosing the right material for the job ensures the best performance.

Key Takeaway

Successful construction starts with choosing the right building inputs. Contractors must source materials that meet the demanding local climate and standards, especially construction materials Philippines. Checking certifications and partnering with good suppliers are important steps. Focusing on high-quality materials improves project outcomes and safety. This careful selection leads to durable, long-lasting structures for clients.

Leave a Reply