As industries grow, their production demands rarely remain static. Volumes increase, product lines diversify, and operational complexity rises. Tooling scalability plays a critical role in supporting this growth by ensuring that tools can adapt to changing requirements without causing delays or excessive costs.

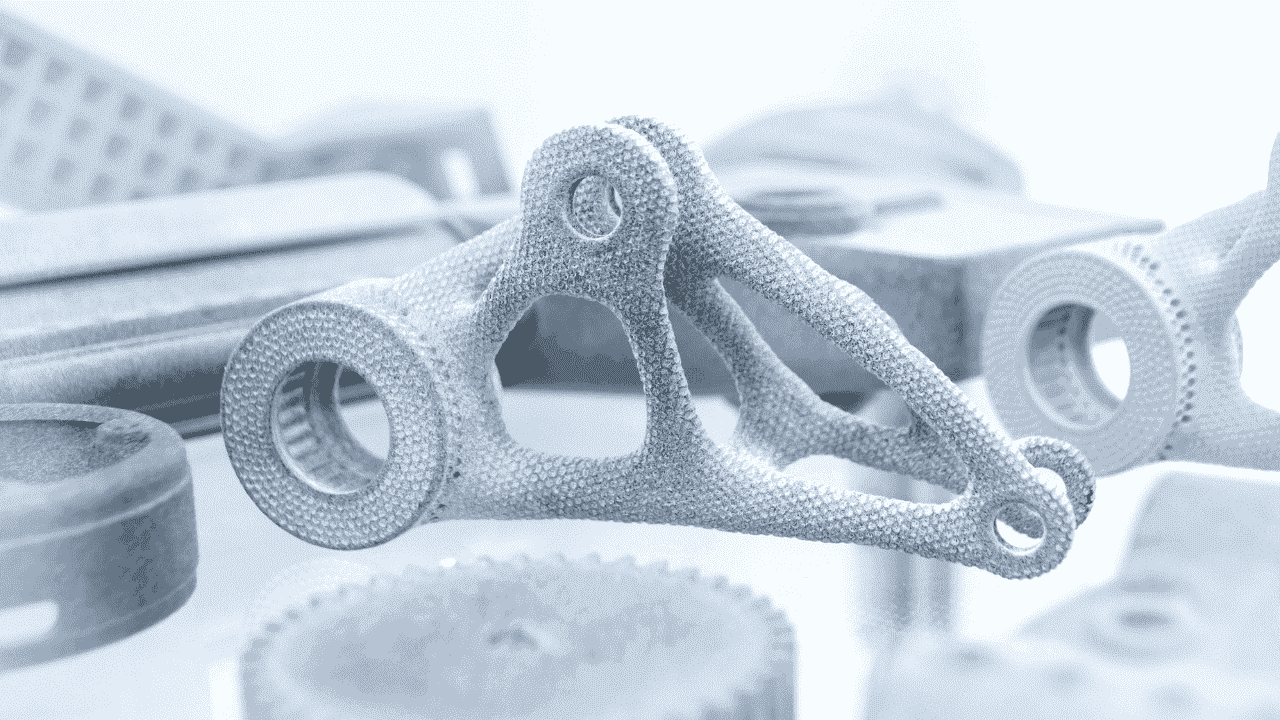

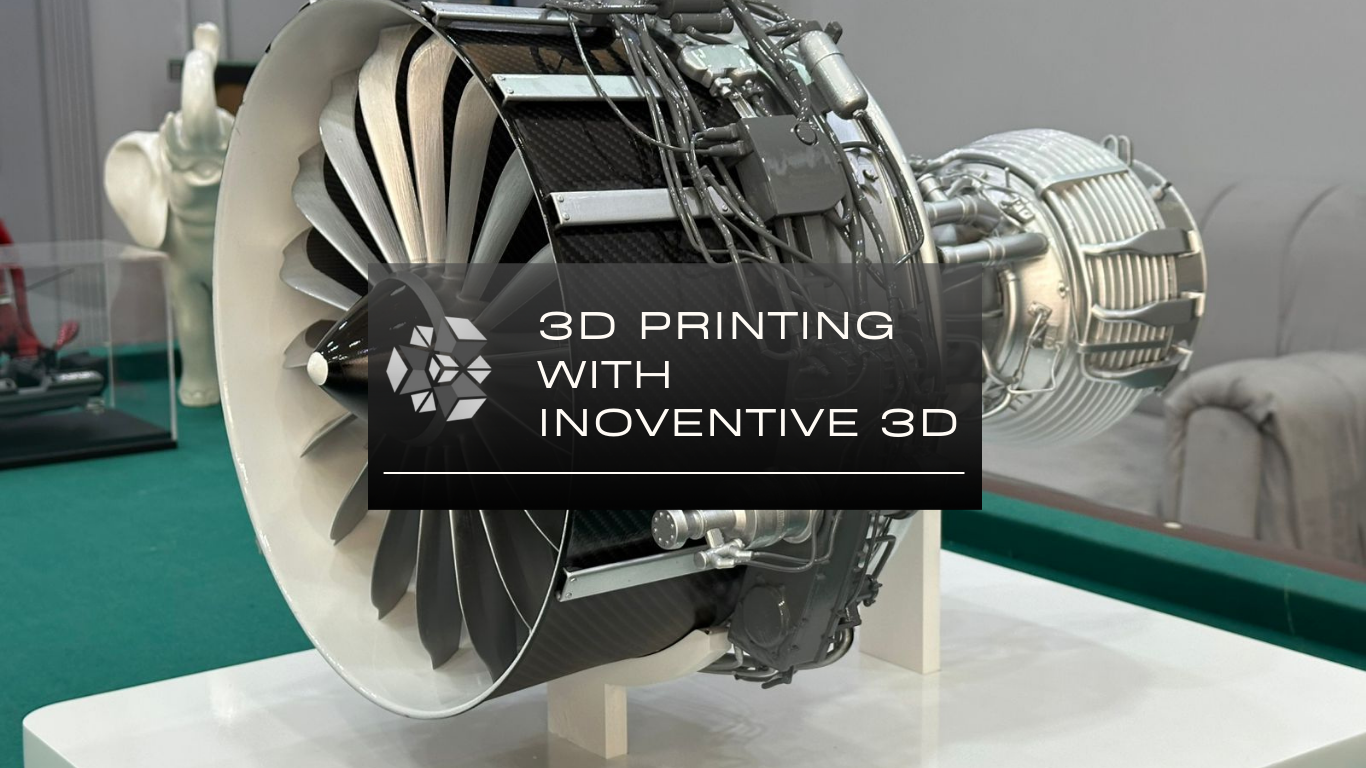

Scalable tooling systems allow businesses to expand production capacity smoothly while maintaining quality, efficiency, and control. Technologies such as 3d printing have further strengthened this capability by enabling flexible and responsive tooling strategies.

Supporting Gradual Production Growth

Growing industries often experience phased expansion rather than sudden large-scale growth. Tooling scalability allows manufacturers to increase output step by step instead of making heavy upfront investments. Tools can be produced, modified, or replicated as demand rises. This approach reduces financial risk and ensures that tooling capacity aligns closely with actual production needs. Businesses can respond confidently to new orders without overextending resources.

Adapting to Product Line Expansion

Industry growth usually brings product diversification. New models, sizes, or variants often require tooling changes. Scalable tooling supports this by allowing existing tools to be adapted or extended rather than replaced entirely.

Modular and customizable tools make it easier to accommodate new designs. With 3d printing Dubai, tools can be redesigned quickly to support new product features while preserving compatibility with existing production systems.

Maintaining Consistency Across Higher Volumes

As production scales up, maintaining consistent quality becomes more challenging. Scalable tooling ensures that accuracy and repeatability remain stable even as output increases. Well-designed tools guide processes consistently, reducing variations that may arise from higher workloads. This consistency is essential for industries that must meet strict quality standards while expanding operations.

Reducing Downtime During Expansion

Rapid growth often puts pressure on production schedules. If tooling cannot keep pace, delays and downtime can disrupt expansion plans. Scalable tooling helps prevent this by enabling quick replication or adjustment of tools when capacity needs increase. With 3d printing, additional tools can be produced locally and rapidly, minimizing disruptions and keeping production lines running smoothly.

Improving Cost Control and Budget Planning

Financial efficiency is crucial during growth phases. Traditional tooling often requires large investments that may not be justified in early expansion stages. Scalable tooling spreads costs over time, allowing businesses to invest gradually. This improves budget planning and ensures that spending remains aligned with growth milestones. Cost-effective production of tools also supports experimentation and innovation without excessive financial risk.

Supporting Workforce Expansion and Training

Growing industries often onboard new workers as production scales. Scalable tooling contributes to smoother workforce integration by simplifying processes. Tools designed for consistency and ease of use reduce dependency on highly specialized skills. This allows new team members to reach productivity faster, supporting expansion without compromising operational efficiency.

Enhancing Flexibility in Supply Chain Operations

Expansion can place strain on supply chains, especially when tooling depends on external suppliers. Scalable tooling reduces this dependency by enabling local production and faster adjustments. With 3d printing, companies can respond quickly to supply disruptions or material changes by producing or modifying tools in-house. This flexibility strengthens resilience during growth periods.

Enabling Innovation Alongside Expansion

Growth does not only involve higher volumes but also innovation. Scalable tooling allows industries to experiment with new processes, materials, and designs while continuing regular production. Tools can be tested, refined, and scaled without long interruptions. This balance between stability and innovation helps growing industries stay competitive and responsive to market trends.

Supporting Multi-Site and Distributed Production

As companies expand geographically, tooling scalability becomes even more important. Consistent tools must be available across multiple locations to ensure uniform production standards. Digitally designed tools can be reproduced accurately at different sites. Using 3d printing, companies can maintain design consistency while allowing local production, supporting efficient multi-site operations.

Strengthening Long-Term Operational Sustainability

Sustainable growth depends on systems that can evolve without excessive waste or inefficiency. Scalable tooling supports this by reducing unnecessary replacements and enabling continuous improvement. Tools can be upgraded or adapted rather than discarded. This approach reduces material waste and supports long-term operational sustainability as industries mature.

Conclusion

Tooling scalability is a foundational element for industries aiming to grow efficiently and sustainably. It supports gradual expansion, product diversification, cost control, and operational consistency.

By enabling rapid adaptation and local production, 3d printing further enhances the ability of businesses to scale tooling alongside demand. For growing industries, scalable tooling is not just a technical advantage but a strategic asset that ensures resilience, flexibility, and long-term success.

Expansion can place strain on supply chains, especially when tooling depends on external suppliers. Scalable tooling reduces this dependency by enabling local production and faster adjustments. With 3d printing, companies can respond quickly to supply disruptions or material changes by producing or modifying tools in-house. This flexibility strengthens resilience during growth periods.

Leave a Reply