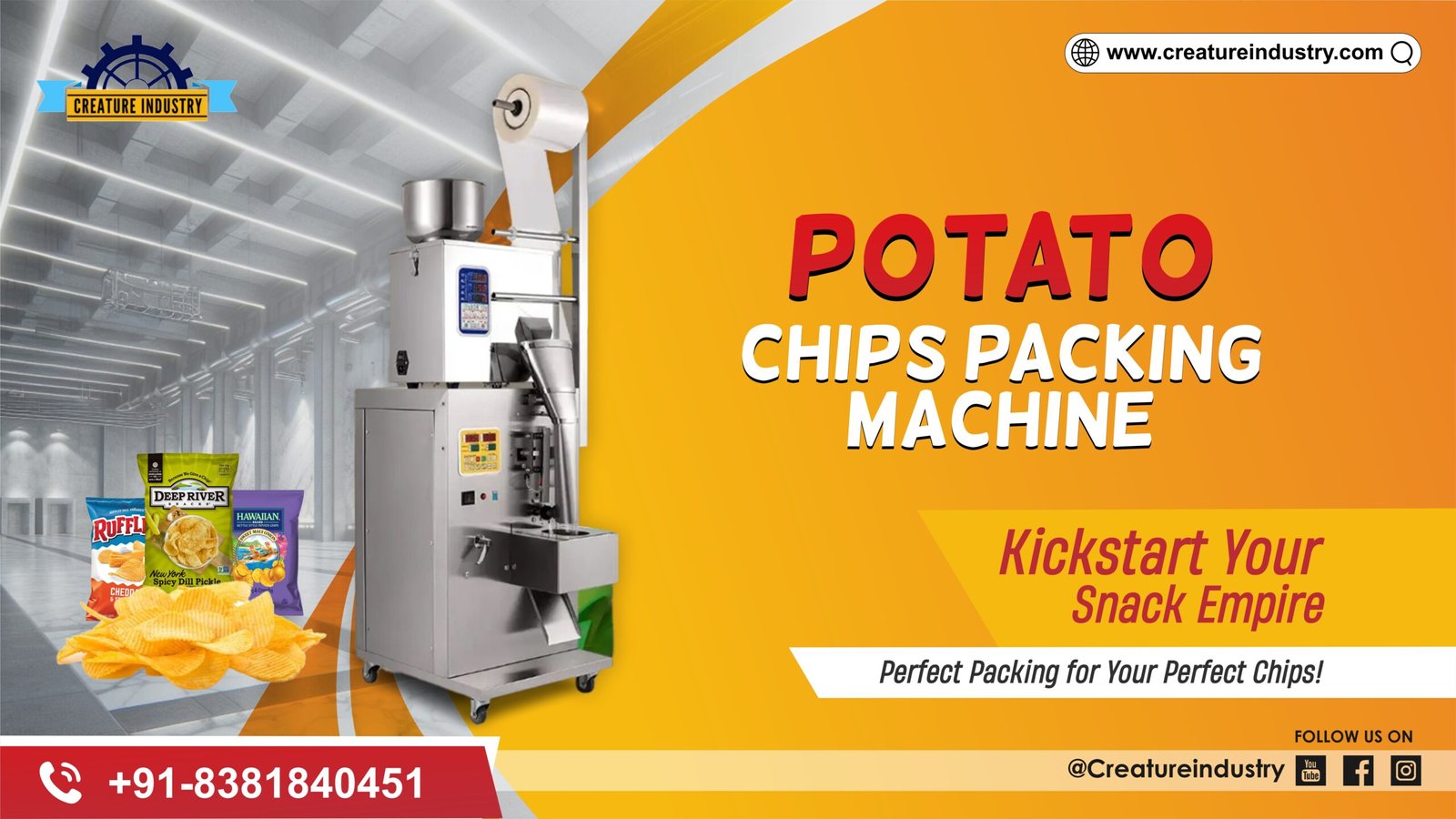

Introduction to Chips Packing Machines

In the modern food industry, Chips Packing Machines play a crucial role in ensuring efficient, hygienic, and high-speed packaging of chips and snacks. These machines not only help maintain the freshness and crispness of chips but also enhance production efficiency, minimize wastage, and ensure uniform packaging.

With the rising demand for packaged snacks, businesses need automated packing solutions to keep up with market trends. Whether you run a small snack business or a large-scale chips manufacturing plant, investing in a high-quality chips packing machine is essential.

Types of Chips Packing Machines

1. Automatic Chips Packing Machine

An automatic chips packing machine is designed for large-scale production. It offers high-speed packaging with minimal manual intervention. Features include:

- PLC control system for precision and efficiency

- Multi-head weighers for accurate weight measurement

- Sealing and cutting mechanisms to ensure airtight packaging

- High-speed operation to meet bulk production demands

2. Semi-Automatic Chips Packing Machine

Ideal for small to medium-scale businesses, semi-automatic chips packing machines require partial manual input but still offer fast and efficient packaging. Key features include:

- User-friendly controls

- Adjustable speed settings

- Cost-effective operation

- Suitable for various packaging materials

3. Vertical Form Fill Seal (VFFS) Machine

A VFFS machine is widely used for packing chips. It forms the bag, fills it with chips, and seals it in one continuous process. Features include:

- High-speed automation

- Accurate portion control

- Customizable bag sizes

- Efficient nitrogen flushing to preserve freshness

Key Features to Consider in a Chips Packing Machine

1. Speed and Efficiency

A high-speed chips packing machine can significantly improve productivity. The speed varies depending on the model, but modern machines can pack up to 100 bags per minute.

2. Packaging Material Compatibility

These machines support various packaging materials, including:

- Laminated plastic films

- Aluminum foils

- Paper-based materials

- Biodegradable packaging films

3. Nitrogen Flushing System

To maintain crispness and extend shelf life, nitrogen flushing removes oxygen from the packaging, preventing oxidation and staleness.

4. Weighing and Filling Accuracy

Equipped with advanced multi-head weighers, modern chips packing machines ensure precise weight measurement, reducing product wastage.

5. Sealing and Cutting Mechanisms

Strong sealing ensures that the packets remain airtight. Heat sealing, ultrasonic sealing, and zipper sealing are common options.

Benefits of Using a Chips Packing Machine

1. Increased Production Capacity

Automated chips packing machines boost packaging speeds, allowing manufacturers to scale operations efficiently.

2. Improved Product Freshness

The use of nitrogen flushing and airtight sealing ensures that chips remain fresh and crispy for a longer period.

3. Cost Savings

Automation reduces labor costs, material wastage, and operational expenses, making production more cost-effective.

4. Customizable Packaging Options

From pillow pouches to stand-up pouches, businesses can choose from a variety of packaging styles to enhance brand visibility.

How to Choose the Best Chips Packing Machine?

1. Consider Your Production Needs

Determine whether you need a semi-automatic or fully automatic machine based on your production volume.

2. Check for After-Sales Support

Ensure that the manufacturer provides technical support, spare parts availability, and warranty for seamless operation.

3. Evaluate the Machine’s Compatibility

Make sure the machine supports your preferred packaging material, bag size, and sealing method.

4. Look for Energy-Efficient Models

Energy-efficient machines help reduce power consumption and operational costs.

Top Chips Packing Machine Manufacturers

Several brands manufacture high-quality chips packing machines. Some leading names include:

- Ishida – Known for precision weighing and high-speed packaging solutions.

- Heat and Control – Offers reliable and innovative snack packaging systems.

- Creature Industry – Provides top-quality chips packing machines with advanced features and a 10% discount on purchases.

- Syntegon (Bosch Packaging) – Offers state-of-the-art automation in food packaging.

Maintenance Tips for Chips Packing Machines

1. Regular Cleaning

Proper cleaning prevents contamination and ensures hygienic packaging. Use food-grade cleaning solutions to maintain machine hygiene.

2. Lubrication of Moving Parts

Regular lubrication extends the life of components like sealing jaws, belts, and motors.

3. Periodic Calibration

Calibrate weighing and filling mechanisms to maintain accuracy in weight measurement.

4. Inspect Electrical Components

Check wiring, sensors, and control systems for any issues to prevent machine downtime.

5. Replace Worn-Out Parts

Regularly replace sealing bars, heating elements, and cutting blades to maintain efficiency.

Conclusion

Investing in a chips packing machine is essential for businesses looking to scale operations while maintaining high packaging quality, freshness, and efficiency. With advanced features like nitrogen flushing, precision weighing, and customizable packaging, these machines enhance production capabilities and meet market demands effectively.

If you are looking for top-quality chips packing machines, consider Creature Industry for reliable solutions and an exclusive 10% discount on your purchase.

Frequently Asked Questions (FAQs)

1. What is the best type of chips packing machine for small businesses?

For small businesses, a semi-automatic chips packing machine is ideal as it offers cost-effective and efficient packaging.

2. How does nitrogen flushing help in chips packaging?

Nitrogen flushing removes oxygen from the packet, preventing oxidation and keeping chips fresh and crispy for a longer time.

3. Can I use biodegradable packaging materials with chips packing machines?

Yes, most modern chips packing machines support biodegradable and eco-friendly packaging materials.

4. How often should I maintain my chips packing machine?

Regular maintenance, including cleaning, lubrication, and calibration, should be done at least once a month to ensure smooth operation.

5. What is the average speed of a chips packing machine?

Depending on the model, chips packing machines can pack 50 to 100 bags per minute.

Leave a Reply