Steel is a foundational material for national development. It supports infrastructure, construction, and manufacturing industries. In the Philippines, the sector faces unique dynamics. Understanding the challenges facing steel suppliers in the Philippines is crucial for growth. Yet, alongside these hurdles lie significant opportunities. Navigating this complex landscape requires strategic insight and adaptability.

What Defines the Steel Supply Landscape in the Philippines?

The Philippine steel industry is a mix of local production and significant imports. Local mills primarily produce rebar and some long products. Flat steel products and specialized steel are largely imported. This reliance on imports makes the market sensitive to global conditions. Demand is driven by the country’s robust construction and manufacturing sectors. The “Build, Build, Build” program has notably increased steel consumption.

Key Players and Operations

Steel suppliers range from large importers and distributors to smaller local traders. Their roles include sourcing, warehousing, and distributing various steel products. Quality control, timely delivery, and competitive pricing are key. They must ensure that steel meets Philippine National Standards (PNS). The sector is continuously evolving to meet market demands.

Why Address Challenges and Seize Opportunities?

Addressing challenges is essential for sustainability. Overcoming hurdles ensures stable operations and continued profitability. It strengthens the local industry against external shocks. Proactive strategies allow businesses to maintain competitiveness. Identifying and capitalizing on opportunities is equally vital.

Global Price Volatility

One major reason for challenges is global price volatility. Steel prices are influenced by international supply and demand. Geopolitical events and trade policies also play a part. Fluctuating prices make inventory management difficult. It also creates uncertainty in pricing for customers. Suppliers must absorb or pass on these unpredictable costs.

Intense Import Competition

Another key challenge is intense import competition. The Philippines imports a large portion of its steel, especially from countries like China. These imports can sometimes be cheaper, making it hard for local suppliers to compete. Substandard or smuggled steel further complicates the market. This unfair competition undermines legitimate businesses.

Logistical Complexities

Logistical complexities also pose a significant hurdle. Transporting heavy steel products across an archipelago is costly. Port congestion and poor infrastructure add to delays and expenses. Efficient last-mile delivery is challenging in many areas. These logistical issues impact delivery times and overall costs.

Regulatory Compliance

For challenges facing steel suppliers in the Philippines, regulatory compliance is also a factor. The Department of Trade and Industry (DTI) sets strict quality standards for steel products. Ensuring all imported and locally distributed steel meets these standards requires careful monitoring. Non-compliance can lead to severe penalties. Keeping up with evolving regulations can be demanding.

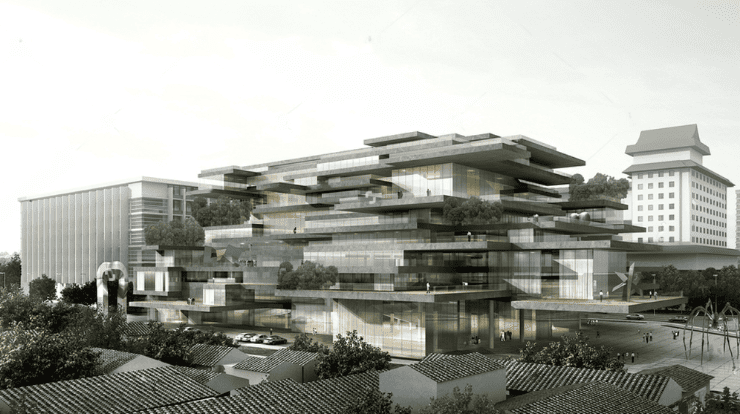

Infrastructure Boom

On the other hand, immense opportunities exist. The Philippines’ rapid urbanization fuels construction. The government’s continued focus on infrastructure development creates consistent demand. The “Build, Build, Build” program, for instance, drives massive steel consumption. This provides a steady market for suppliers.

Manufacturing Sector Growth

Growth in the manufacturing sector also presents opportunities. Local industries are expanding production of vehicles, appliances, and machinery. This diversification increases the demand for various specialized steel types. Suppliers can cater to these evolving needs. Supporting local manufacturing strengthens the economy.

Digital Transformation

Embracing digital transformation is another key opportunity. E-commerce platforms can streamline order processing and distribution. Data analytics can improve inventory management and forecasting. Digital tools enhance customer experience and operational efficiency. They can create new sales channels.

Sustainability and Green Steel

Sustainability and green steel initiatives also open new avenues. There is a growing global demand for environmentally friendly products. Suppliers adopting sustainable practices can attract new clients. Investing in green technologies offers long-term benefits. This aligns with global climate goals.

How Steel Suppliers in the Philippines Can Navigate the Landscape

To overcome challenges facing steel suppliers in the Philippines and seize opportunities, a multi-faceted approach is needed.

Strategic Sourcing and Diversification

To mitigate price volatility, diversify import sources. Explore new markets beyond traditional suppliers. Foster stronger relationships with local mills. Having multiple sources enhances supply chain resilience. It reduces reliance on any single market.

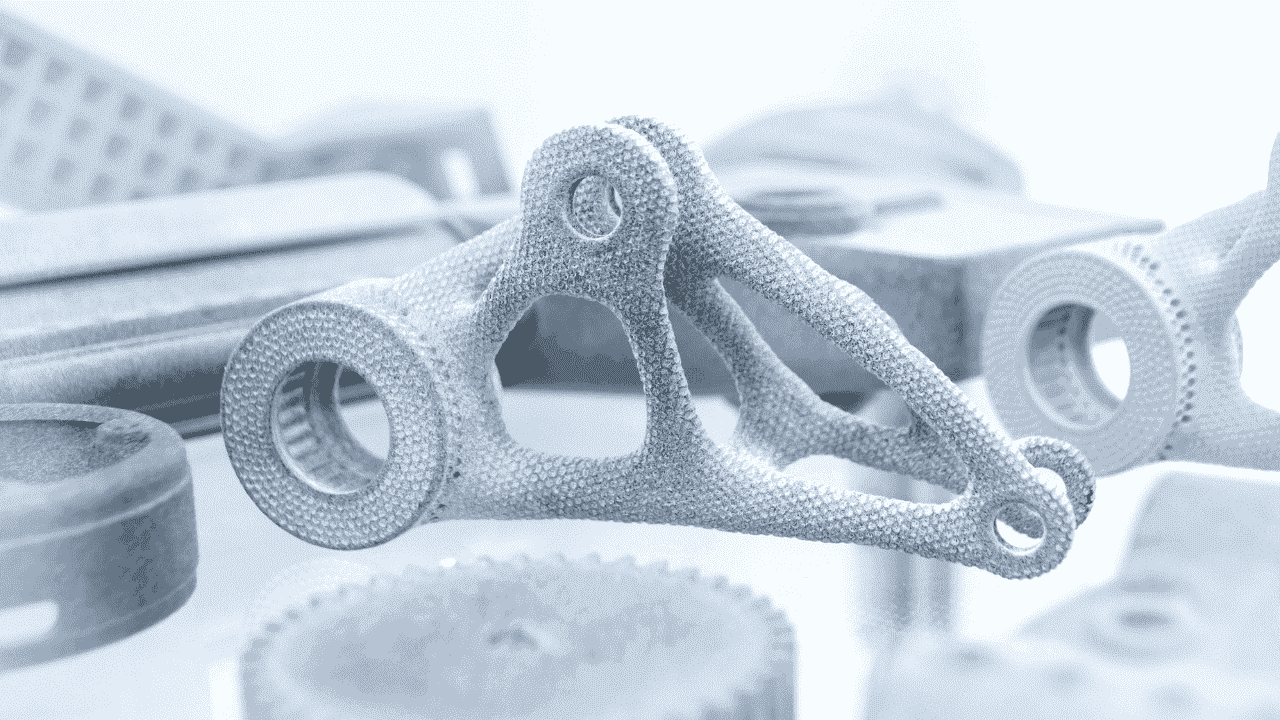

Enhance Local Value-Adding Services

Offer services beyond just supplying raw steel. This includes cutting, bending, fabrication, and customized solutions. Value-added services increase profitability and differentiate suppliers. They meet specific needs of manufacturers and contractors.

Invest in Logistics and Warehousing

Improve storage facilities and transportation networks. Implement modern inventory management systems. Optimize delivery routes to reduce costs and lead times. Efficient logistics directly impacts customer satisfaction. It creates a competitive advantage.

Strengthen Quality Control and Compliance

Implement rigorous quality checks for all incoming and outgoing steel. Ensure all products comply with DTI-BPS standards. Promote transparency in product certification. This builds trust and combats substandard products. It protects the integrity of the market.

Leverage Technology and Digitalization

Adopt e-commerce platforms for easier ordering and tracking. Use data analytics for demand forecasting and inventory optimization. Implement automation in warehousing. Digital tools streamline operations and enhance customer service.

Build Strong Customer Relationships

Develop long-term partnerships with contractors and manufacturers. Offer excellent customer service and technical support. Understand their evolving needs. Strong relationships lead to repeat business and referrals.

Advocate for Fair Trade Policies

Collaborate with industry associations to advocate for policies against unfair imports and smuggling. Support government efforts to enforce quality standards. A level playing field benefits all legitimate businesses. It fosters a healthier market environment.

Explore Green and Sustainable Practices

Invest in energy-efficient operations. Explore sourcing from mills that use cleaner production methods. Promote recycled steel where applicable. Embracing sustainability appeals to environmentally conscious clients. It positions suppliers for future market trends.

Key Takeaway

The steel supply sector in the Philippines operates in a dynamic environment. While challenges facing steel suppliers in the Philippines like price volatility and import competition are real, significant opportunities abound. By strategically adapting, embracing innovation, and focusing on quality and customer service, suppliers can thrive. Their success is integral to the continued growth and industrialization of the Philippine economy.

Leave a Reply