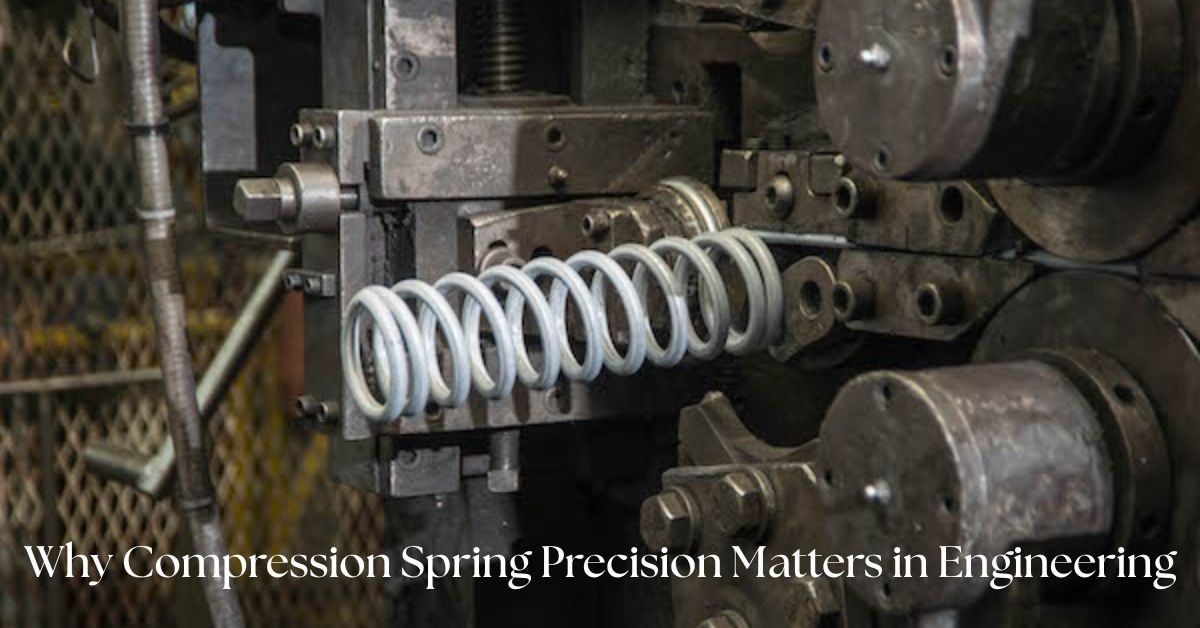

In modern engineering, even the smallest components play a critical role in determining overall system performance. Among these components, compression springs are widely used across industries such as automotive, aerospace, electronics, and heavy machinery. Precision in compression spring design and manufacturing directly impacts safety, efficiency, and product lifespan. This is why engineers increasingly rely on experienced Compression Spring Suppliers who can deliver consistent quality and exact specifications for demanding applications.

Understanding Compression Springs in Engineering Systems

Compression springs are designed to resist compressive forces and return to their original shape when the load is removed. They are commonly used to absorb shock, maintain force between components, and control motion. In engineering systems, these springs often operate under continuous stress, extreme temperatures, or repetitive cycles. Even minor deviations in dimensions, load capacity, or material quality can lead to performance failures or unexpected breakdowns.

Precision ensures that compression springs perform exactly as intended, maintaining stability and reliability in complex assemblies.

The Role of Precision in Performance and Safety

Engineering applications demand predictable performance. Precision-manufactured compression springs provide accurate load rates, uniform stress distribution, and consistent free length. This accuracy helps prevent issues such as buckling, uneven wear, or sudden failure.

In safety-critical applications like braking systems, medical devices, or industrial machinery, a poorly manufactured spring can compromise the entire system. Precision directly contributes to operational safety by ensuring controlled movement and reliable force output under all working conditions.

Impact on Durability and Product Lifespan

A precisely engineered compression spring experiences less internal stress and fatigue during operation. This results in longer service life and reduced maintenance requirements. When springs are manufactured with tight tolerances and proper heat treatment, they can withstand millions of compression cycles without losing strength or shape.

For manufacturers, this durability translates into fewer replacements, lower downtime, and improved customer satisfaction. Precision is not just a quality factor, it is a long-term cost-saving advantage.

Precision Manufacturing and Material Selection

Achieving precision starts with selecting the right raw materials. Factors such as tensile strength, corrosion resistance, and elasticity must align with the application’s requirements. Advanced manufacturing processes, including CNC coiling, controlled heat treatment, and rigorous testing, further enhance accuracy.

Reputable suppliers invest in modern equipment and quality control systems to ensure every spring meets exact engineering standards. This level of precision is especially important in industries where consistency across large production volumes is essential.

Importance of Reliable Suppliers in Engineering Projects

Midway through an engineering project, sourcing becomes a strategic decision. Choosing a dependable Spring Manufacturer in Chennai ensures access to technically sound compression springs that meet both domestic and international standards. Experienced manufacturers understand industry-specific challenges and offer customization options to match unique design requirements.

Working with skilled manufacturers also enables engineers to collaborate on design improvements, material upgrades, and performance optimization, resulting in better end products.

Customization and Engineering Accuracy

No two engineering applications are exactly the same. Precision allows compression springs to be customized in terms of wire diameter, outer diameter, free length, and load capacity. This customization ensures perfect integration into assemblies without the need for design compromises.

Effect of Precision on System Efficiency

Precision-engineered compression springs contribute significantly to overall system efficiency. When springs operate with accurate force and alignment, energy loss due to friction, vibration, or misalignment is minimized. This leads to smoother mechanical operation and improved energy utilization across the system.

Precision Tolerances and Load Accuracy

Precision tolerances play a crucial role in ensuring compression springs deliver exact load and deflection characteristics. Even slight variations in coil spacing or wire diameter can alter force output, leading to inefficiencies or mechanical imbalance. Accurate tolerances help engineers maintain consistent load performance, especially in applications requiring repeated motion and controlled pressure. This accuracy supports smoother operation and reduces the risk of component failure over time.

Quality Testing and Compliance Standards

Rigorous quality testing is essential to maintain compression spring precision in engineering applications. Load testing, dimensional checks, and fatigue testing help verify that each spring meets required specifications and industry standards. Compliance with recognized standards ensures reliability across different operating conditions and environments. Such quality assurance measures give engineers confidence that the springs will perform consistently throughout their service life.

Conclusion

Precision in compression springs is a fundamental requirement in engineering, not an optional feature. It directly affects performance, safety, durability, and overall system efficiency. From accurate load handling to extended service life, precision-engineered compression springs contribute significantly to reliable engineering outcomes.

By partnering with experienced suppliers and manufacturers who prioritize quality and accuracy, engineers can ensure their systems operate smoothly under demanding conditions. Ultimately, precision in compression springs is a cornerstone of engineering excellence and long-term product success.

Leave a Reply