Industrial infrastructure relies on robust, reliable components to ensure seamless operations. Among these components, mild steel threaded flanges stand out as versatile and essential elements across various applications. From pipelines to machinery, these flanges play a critical role in joining, sealing, and maintaining industrial systems.

This article delves into the unique features, advantages, and diverse uses of ms threaded flanges in industrial settings.

What Are Mild Steel Threaded Flanges?

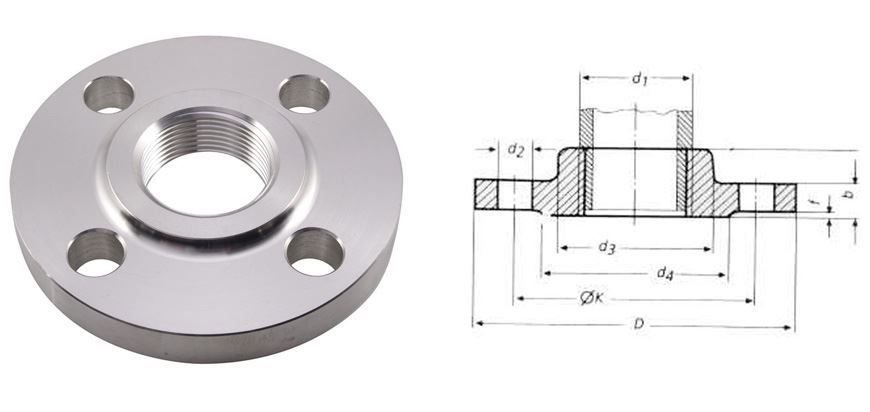

MS threaded flanges are circular components used to connect pipes, valves, or equipment. Unlike welded flanges, they rely on threads to secure connections, eliminating the need for welding. Mild steel, characterized by its low carbon content, lends these flanges a perfect balance of strength, ductility, and affordability.

Threaded flanges are particularly suitable for low-pressure and non-critical applications, making them a favourite in industries where ease of installation and maintenance is crucial.

Key Features of Mild Steel Threaded Flanges

- Threaded Design: These flanges have internal threads that align with the external threads of a pipe, ensuring a tight and leak-proof connection.

- Corrosion Resistance: MS threaded flanges can be treated with coatings or galvanized to enhance their resistance to corrosion.

- High Ductility: Mild steel’s ductility allows for easy machining and customization, catering to specific industrial needs.

- Ease of Installation: The threaded design eliminates the need for welding, making installation faster and safer.

Advantages of Mild Steel Threaded Flanges

- Cost-Effectiveness

MS threaded flanges are a budget-friendly solution without compromising on quality. Their affordability makes them an ideal choice for large-scale projects. - Ease of Maintenance

Since these flanges are not welded, they can be easily dismantled for inspection, cleaning, or replacement, reducing downtime and maintenance costs. - Compatibility with Various Systems

MS threaded flanges are compatible with a wide range of piping systems, including those carrying water, oil, gas, or other fluids. - Durability

Mild steel’s inherent strength ensures that these flanges can withstand moderate pressure and temperature conditions, making them suitable for various industrial environments. - Environmentally Friendly

Mild steel is recyclable, contributing to sustainability efforts in industrial processes.

Applications of Mild Steel Threaded Flanges in Industries

1. Oil and Gas Industry

In oil and gas pipelines, MS threaded flanges are used to join sections of pipes and equipment. Their ability to handle moderate pressures and resist corrosion makes them indispensable in this sector.

2. Chemical Processing Plants

Chemical plants require secure connections to transport chemicals safely. Mild steel threaded flanges provide reliable, leak-proof connections suitable for low-pressure chemical transport.

3. Water Treatment Facilities

Water treatment plants utilize ms threaded flanges in their pipelines to ensure efficient water flow and filtration processes. Their easy installation and maintenance make them ideal for such applications.

4. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems depend on ms threaded flanges to connect ducts and pipelines, ensuring smooth operation and energy efficiency.

5. Power Generation Plants

In power plants, these flanges are used in systems that require frequent dismantling for inspection or maintenance, such as cooling systems or auxiliary pipelines.

6. Manufacturing and Construction

Mild steel threaded flanges are widely used in machinery and construction equipment for secure connections that can be easily adjusted or replaced when needed.

Factors to Consider When Choosing Mild Steel Threaded Flanges

- Pressure and Temperature Ratings

Ensure the flanges meet the operational requirements of your industrial system. - Coating or Galvanization

For environments prone to corrosion, opt for coated or galvanized flanges to enhance longevity. - Thread Compatibility

Check that the internal threads of the flange align perfectly with the external threads of the pipes or equipment. - Compliance with Standards

Always choose flanges that adhere to industry standards such as ASME, ASTM, or ISO for safety and reliability. - Supplier Reputation

Select reputable mild steel threaded flange suppliers to guarantee high-quality products that meet your project’s needs.

Future of Mild Steel Threaded Flanges in Industrial Applications

As industries continue to evolve, the demand for efficient and cost-effective solutions like mild steel threaded flanges will only grow. Innovations in material treatment, such as advanced coatings and anti-corrosion technologies, are further enhancing the performance of these flanges.

Moreover, the shift towards sustainable practices underscores the importance of using recyclable materials like mild steel, making these flanges a valuable asset in modern industrial setups.

Conclusion

Mild steel threaded flanges are a versatile and reliable solution for various industrial applications. Their affordability, durability, and ease of installation make them a preferred choice in industries ranging from oil and gas to construction and water treatment.

By choosing high-quality MS threaded flanges from trusted suppliers, industries can ensure the efficiency, safety, and longevity of their systems. With advancements in technology and a focus on sustainability, these flanges will continue to play a crucial role in shaping the future of industrial infrastructure.

Leave a Reply