In the world of industrial and commercial weighing, precision is paramount. Whether it’s manufacturing, transportation, or scientific research, the accuracy of measurements directly impacts efficiency, quality, and compliance. At the heart of these precise measurements is the load cell—a crucial component that converts force into measurable electrical signals. To ensure these readings remain reliable, load cell calibration services are essential. Let’s explore the science behind load cell calibration and its importance in achieving precise weighing.

What is a Load Cell?

A load cell is a transducer designed to measure weight or force. When a load is applied, the load cell produces an electrical signal proportional to the weight. Common types of load cells include:

- Strain Gauge Load Cells – These measure changes in electrical resistance.

- Hydraulic Load Cells – These use fluid displacement to gauge force.

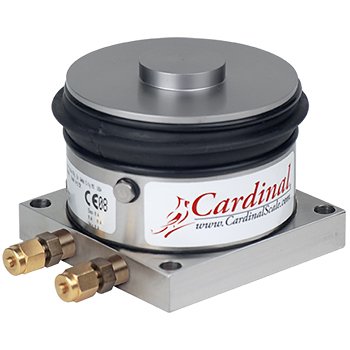

- Pneumatic Load Cells – These rely on air pressure for measurement.

Each type is used in different applications, from heavy-duty truck scales to delicate scientific balances. Regardless of the type, load cells require periodic calibration to ensure their readings are accurate and consistent.

Understanding Load Cell Calibration

Load cell calibration is the process of verifying and adjusting a load cell’s output to match known standards. Over time, factors such as environmental conditions, wear and tear, and mechanical stress can cause inaccuracies. Calibration helps detect and correct these errors, ensuring the load cell continues to deliver precise results.

The Science Behind Calibration

Calibration involves comparing a load cell’s output against a certified reference standard. Here’s how the process works:

- Application of Known Weights

Technicians apply a series of certified weights to the load cell. These weights serve as benchmarks for measurement accuracy. - Measuring Output

The load cell’s electrical signal is recorded for each weight. This signal is usually in the form of millivolts or digital readings. - Identifying Deviations

The recorded output is compared to the expected values based on the known weights. Any discrepancies indicate the load cell’s deviation from accuracy. - Adjustment and Correction

If deviations are identified, adjustments are made to the load cell’s internal circuitry or software settings.

Why Load Cell Calibration Services Matter

Accurate load cell calibration ensures that measurements remain within acceptable tolerance levels. Here’s why professional load cell services are critical:

Regulatory Compliance

Industries such as pharmaceuticals, food processing, and transportation must adhere to strict regulations. Calibration ensures compliance with industry standards.

Quality Assurance

Precise measurements guarantee the consistency and quality of products, reducing waste and improving customer satisfaction.

Cost Savings

Errors in weight measurement can lead to overloading fines, product recalls, or underbilling customers. Calibration minimizes these risks.

Longevity of Equipment

Regular calibration reduces wear and tear, extending the lifespan of load cells.

If you’re looking to maintain accuracy, you could check here for professional load cell calibration services that ensure compliance, quality, and cost efficiency.

Factors Affecting Load Cell Calibration

Several factors influence the accuracy and frequency of load cell calibration:

Environmental Conditions

Temperature, humidity, and vibrations can affect load cell performance.

Load Cell Overloading

Applying excessive weight can damage the load cell and skew its readings.

Frequency of Use

Load cells used daily or in high-volume operations require more frequent calibration.

Mechanical Stress

Improper installation or physical damage can alter a load cell’s performance.

When to Calibrate Your Load Cell

Regular calibration schedules depend on the specific application, usage frequency, and industry standards. However, here are common triggers for scheduling calibration:

- After installation or relocation.

- Following an overload event.

- When accuracy concerns arise.

- As part of annual maintenance.

The Importance of Certified Calibration Services

Professional calibration services use certified reference standards and adhere to international guidelines. Here’s why opting for certified services matters:

Traceability

Calibration records provide traceability to national or international standards.

Expertise

Certified technicians understand the nuances of different load cell types and applications.

Advanced Equipment

Calibration labs use sophisticated tools to ensure accurate and reliable adjustments.

To maintain your load cell’s accuracy and reliability, go right here for certified calibration solutions.

Benefits of Choosing the Right Load Cell Calibration Services

Investing in professional calibration services offers numerous advantages:

- Improved Accuracy: Keep measurements within tolerance levels.

- Enhanced Productivity: Reduce downtime caused by faulty equipment.

- Greater Confidence: Assure stakeholders of precise and reliable results.

Get more information about how expert calibration services can transform your weighing operations.

DIY Calibration vs. Professional Services

While some companies attempt in-house calibration, professional services provide several key benefits:

- Specialized Equipment: Professionals use advanced calibration tools.

- Expertise: Trained technicians ensure accurate results.

- Compliance: Certified services meet regulatory requirements.

Conclusion

Load cell calibration is more than a routine task—it’s a critical process that ensures precision, compliance, and cost savings in various industries. Whether you’re weighing cargo on truck scales or measuring raw materials in a factory, accurate calibration is essential.

By understanding the science behind load cell calibration and partnering with professional services, you can maintain reliable and consistent measurements, enhance operational efficiency, and achieve peace of mind. If you’re ready to optimize your weighing systems, you can find out more about load cell calibration services offered by trusted professionals.

Leave a Reply