Swapping a Cummins diesel engine into a gas or older diesel vehicle is a dream project for many truck and off-road enthusiasts. The torque, durability, and fuel efficiency of Cummins engines—especially the legendary 5.9L and 6.7L—is unmatched in the aftermarket world. But while the engine may be the star of the show, the Cummins conversion parts you choose are what truly make or break the swap.

Buying the right components is essential to avoid costly setbacks, compatibility issues, or safety risks. Whether you’re doing a DIY conversion or working with a professional mechanic, here are the top 5 mistakes to avoid when buying Cummins conversion parts.

1. Ignoring Compatibility Between Engine and Chassis

One of the most common (and costly) mistakes is not checking for compatibility between your Cummins engine and the chassis it’s going into. Cummins engines can be swapped into Ford, Chevy, Dodge, Jeep, and even Toyota platforms—but each has specific requirements.

For example, a 12-valve 5.9L Cummins going into a Ford F-250 will require a completely different set of adapter plates, motor mounts, and transmission solutions than the same engine going into a Chevy square body. Some parts are universal, but many are not. Always double-check engine-to-frame fitment, transmission matchups, and wiring compatibility before ordering any components.

Tip: Consult conversion-specific forums, YouTube builds, or even part manufacturers who specialize in your exact swap combination.

2. Choosing Cheap or Low-Quality Parts

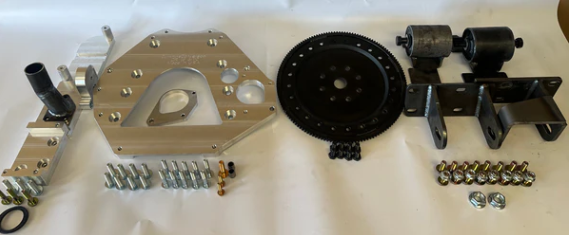

Tempted by bargain prices? Don’t be. Low-quality Cummins conversion parts may seem like a deal, but they often lead to big problems—misalignment, cracked brackets, poor fuel efficiency, or even engine damage. The most important parts to buy from a trusted source include:

- Adapter plates

- Motor mounts

- Transmission crossmembers

- Wiring harness adapters

- Cooling and fuel system upgrades

Using low-grade or poorly machined parts can compromise safety and performance. Stick with reputable brands and suppliers who offer warranties and technical support.

Tip: Look for companies with a track record in Cummins swaps and reviews from real customers doing similar conversions.

3. Overlooking the Electrical and Wiring Aspects

Wiring is often underestimated when it comes to engine conversions. Many DIY builders focus on the physical fit of the engine and neglect the complexities of integrating the new engine’s electronics with the vehicle’s existing systems.

Modern Cummins engines like the 6.7L use CAN bus systems and advanced electronic controls. Even older 12-valve models will still require proper tachometer feeds, sensor inputs, and potentially ECM reprogramming.

Tip: Plan for your wiring early and consider using a plug-and-play wiring harness designed for your engine/chassis combo. These can save dozens of hours and prevent costly mistakes.

4. Failing to Account for Supporting Mods

The engine may be the biggest component in your build, but it’s not the only one that needs attention. Many buyers make the mistake of purchasing Cummins conversion parts without considering what supporting modifications are necessary for the Cummins engine conversion to run safely and efficiently.

Commonly overlooked supporting mods include:

- Upgraded brakes to handle extra engine weight

- Heavy-duty suspension components

- Stronger driveline parts (U-joints, driveshafts)

- Cooling upgrades (larger radiators, intercoolers)

- Fuel system changes (lift pumps, fuel filters)

Failing to upgrade these systems can reduce performance and safety—or even lead to mechanical failure.

Tip: Build a checklist that includes not just engine parts, but all vehicle systems affected by the added power and weight.

5. Not Planning for Local Emissions Laws

In the excitement of sourcing parts, many builders forget to check local emissions regulations. Depending on your location, engine swaps must meet specific criteria to be street-legal. This might include keeping emissions equipment, matching the engine model year to the vehicle, or passing a visual or OBD-II inspection.

States like California have especially strict laws that could make your Cummins conversion illegal for street use if done improperly.

Tip: Contact your local DMV or emissions regulatory agency before you begin your build. This can help you plan a legal, inspection-ready conversion and avoid future registration headaches.

Invest in Research and Ask for Help

Finally, remember that you don’t have to go it alone. The Cummins swap community is full of experienced builders, mechanics, and enthusiasts who are willing to share their knowledge. Whether it’s through online forums, Facebook groups, YouTube tutorials, or manufacturer tech support, take advantage of the collective experience out there.

Asking the right questions before purchasing parts can help you avoid trial-and-error frustration and lead to a more successful, efficient conversion. In a project as complex as an engine swap, solid research and trusted advice can be just as valuable as the parts themselves.

Final Thoughts

A Cummins engine swap can breathe new life into an old truck or give your rig the power and reliability it’s been missing. But success lies in the details—and that starts with choosing the right Cummins conversion parts. By avoiding these five common mistakes, you’ll save time, money, and frustration—and be much more likely to enjoy a smooth-running, street-legal, and badass diesel-powered machine.

Do your homework, invest in quality, and treat your build like the long-term project it is. The payoff is well worth it.

Leave a Reply