Introduction

In industrial settings, every mechanical component contributes to performance and longevity — and pillow block bearing India selection is no exception. With conveyor shafts, pulleys, fans, extruders and other rotating machinery being the backbone of manufacturing, choosing the right mounted bearing unit is crucial. This guide goes beyond the generic advice, and provides practical criteria and India-specific considerations that will help you make better bearing choices in heavy-duty and precision applications.

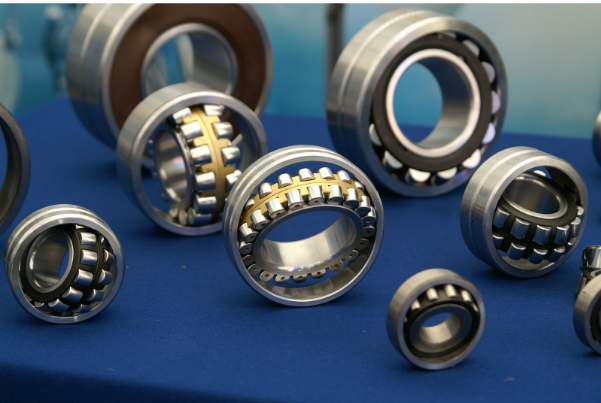

Understanding the Basics of Pillow Block Bearings

Before digging into selection criteria, it’s essential to grasp what constitutes a quality mounted bearing unit in the Indian industrial landscape.

A pillow block bearing comprises a housing (the “block”) and an insert bearing that supports a rotating shaft. The housing is typically mounted on a base and aligned so the shaft axis is parallel to the mounting surface. As noted in engineering reference material, key dimensions such as bore, shaft height, maximum speed and load capacity define the basic specification set.

In Indian industrial practice, housings may be cast-iron, pressed steel or even polymer in specialised environments. Insert bearings are often self-aligning to compensate for misalignment and vibration, and the design must accommodate lubrication, sealing and maintenance access.

When scanning offers of pillow block bearing India, ensure you don’t treat price as the only factor — the thermal, vibration and maintenance environment in India varies widely, so the right bearing system must address those realities.

Match the Application Load & Speed Profile

Selecting a unit purely by nominal bore size is a common trap. Instead, the following three factors must be evaluated together:

Load magnitude and type. It’s vital to identify static loads (shaft at rest) and dynamic loads (shaft in motion), including radial and axial components and any moment (cantilever) loads. For example, conveyor rollers may impose high dynamic radial loads plus moment loads from long spans. Some standard guides observe that roller-style mounted bearings can support high dynamic loads whereas ball types may struggle with sustained moments.

Speed of rotation. The rotational speed interacts with lubricant behaviour, bearing internal stress and heat dissipation. Higher speeds demand bearings with appropriate groove geometry, raceway finish and temperature control.

Duty cycle and shock/impact conditions. If the shaft frequently starts/stops, reverses or experiences shock loads (such as in mining or heavy-duty processing), then the chosen unit must tolerate fatigue and potential misalignment, not simply steady operation. Some leading manufacturers produce heavy-duty styles with split housings and spherical roller inserts precisely for such conditions.

Putting this together: when purchasing a pillow block bearing India, avoid simply matching bore size. Instead model the actual load-and-speed combination, factoring any environment-specific shock. A correctly rated bearing avoids early fatigue failure, overheating or misalignment-induced wear.

Material and Housing Construction That Suit Indian Conditions

Material quality and construction affect durability far more in real-world conditions than simple nominal load ratings. Several detailed points matter:

Housing material choices. Cast iron remains the workhorse for heavy industry due to its rigidity, vibration damping and cost effectiveness. For lighter loads or corrosive environments, pressed steel or polymer housings may be used. Some engineered bearings use stainless steel or composite materials for chemical or food-grade applications.

Insert bearing materials. Most insert bearings use high-carbon chromium steel. In corrosive or food environments, stainless or polymer versions may be offered. The lining, cage and sealing arrangement all influence maintenance needs and life.

Sealing and lubrication provisions. Indian industries often operate in dusty, humid or high-temperature environments. Proper sealing (labyrinth, lip seals, greased covers) prevents ingress of grit, moisture and contaminants. Likewise, a bearing housing should allow relubrication if required. Some designs even offer self-lubricating inserts for low-maintenance usage.

Alignment and tolerances. Misalignment is a common cause of mounted bearing failure. A housing that allows some self-alignment or uses spherical inserts can mitigate this. Additionally, correct shaft fits, locking collars or eccentric collars all play a part.

For a buyer of pillow block bearing India, insist on detailed housing drawings, material specs and sealing class. A lower-cost housing may fail prematurely under Indian plant conditions if it lacks proper material grade or sealing defence.

Maintenance, Serviceability and Lifecycle Considerations

Selecting the right bearing isn’t only about initial fit-up: maintenance regime and total lifecycle costs often dominate in industrial environments.

Ease of installation and replacement. Some bearing housings are split design (top cover removable), enabling bearing removal without shaft disassembly. Especially in large plants or heavy equipment, this can save hours of downtime.

Lubrication strategy. Is the bearing pre-lubricated for life? Does the housing include grease nipple(s) or oil ports? Does the insert require frequent relubrication? In dusty Indian plants, greasing access and clean grease paths are vital.

Condition monitoring readiness. Many modern bearing units incorporate features for vibrational monitoring or temperature sensors. Incorporating such features when purchasing a pillow block bearing India pays off in predictive maintenance and reduced unplanned shutdowns.

Service life and warranty data. Ask for life expectancy under the actual duty cycle, ideally provided by the manufacturer for comparable usage. Minimal warranties or vague service-life claims signal risk. Also confirm availability of spare inserts and housing parts domestically — logistics delay can cripple downtime cost.

Cost of downtime vs initial cost. In industrial settings, the cost of breakdown far exceeds bearing unit cost. A premium housing with better sealing and easier service may cost more upfront but deliver far greater value across its life.

Environmental and Regulatory Factors in India

The Indian context presents additional challenges and opportunities which must feed into the selection of mounted bearing units.

Temperature and humidity. Many Indian plants operate at elevated ambient temperatures or outdoors in monsoon conditions. Bearing units must handle higher temperatures (which reduce grease life and increase thermal expansion) and resist moisture ingress. Specifying temperature-rated greases and sealed housings is prudent.

Dust, fly-ash and contamination. Cement plants, power plants, sugar mills and heavy manufacturing facilities commonly face abrasive contamination. Unless the housing provides effective sealing and easy cleaning, the bearing life will shrink. Some vendors offer units with extra high-performance seals for such environments.

Corrosion risk. Coastal plants and chemical environments demand corrosion-resistant materials. In such cases stainless steel or coated housings are justified even if cost is higher.

Make-in-India/manufacturing & supply chain. When sourcing a pillow block bearing India, preference for local manufacture or strong local distributor support matters. Indian-based brands or authorised local stock ensure quicker delivery, local spares, and adequate service back-up. Counterfeit or grey-market imports pose risks of mismatched seals, incorrect tolerances or inferior steel grades.

Regulatory compliance and standards. Following standards like IS (Indian standards) or their international equivalents (ISO/ANSI) is the way to go for traceability and quality. When bearing units are matched to the standards that are recognized, it provides a guarantee in terms of material, manufacturing processes as well as performance that has been documented.

Matching Supplier Capabilities and After-Sales Support

Even a technically excellent bearing unit fails to deliver if supplier support is weak. The following criteria help assess supplier capability:

Specification documentation and traceability. A credible supplier provides material certificates, dimensional drawings, lubrication instructions and maintenance guides. In India, ask for stamped test certificates, batch numbers and warranty cover.

Spare-parts availability. Industrial plants demand fast turn-around. Ensure the supplier stocks inserts, seals, lubrication kits and housings locally or can leverage domestic warehousing for rapid dispatch.

Installation and training support. Some suppliers provide on-site installation assistance, alignment checks, and training for maintenance teams. For complex or heavy machinery, this support is invaluable.

Technical advice and failure-analysis. A vendor who supports bearing failure investigation, vibration monitoring and life-extension guidance adds significant value. Choosing a unit simply on price ignores the broader lifecycle risk.

Service history and references in India. Ask for case-studies or references of similar installations in Indian plants. Local experience mitigates risk of specification mismatch due to tropical climate, dust, high ambient temperature or heavy load environment.

Practical Checklist for Selection — Your Decision-Matrix

Here is a practical decision-matrix for selecting a pillow block bearing India unit — treat this as a go/no-go checklist before purchase.

- Define duty profile accurately

- Shaft diameter, speed (rpm) and orientation (horizontal/vertical)

- Radial, axial and moment loads in real operation

- Operating cycles, shocks, reversals

- Material and housing suitability

- Housing rated material (cast iron, pressed steel, stainless)

- Insert bearing steel grade, sealing class, self-alignment feature

- Ambient conditions: temperature, humidity, contamination, corrosion

- Mounting and fit-up

- Bore size fit to shaft, locking mechanism (setscrew, collar)

- Base mounting holes, ability to align and shim as needed

- Flange vs pedestal vs split housing option as required

- Lubrication and maintenance plan

- Grease or oil required? Grease nipple accessibility?

- Monitoring ports? Sealed for life option?

- Spare parts availability and maintenance schedule

- Supplier and lifecycle support

- Local availability, technical documentation, installation support

- Warranty, case studies in Indian environment

- Ease of replacement and failure analysis service

- Cost-vs-value trade-off

- Initial cost versus likely lifetime cost including downtime risk

- Cost of removal, installation, alignment and commissioning

- Availability of upgrade path (e.g., heavier duty housing for future load increases)

By scoring each of these items (perhaps on a 1-5 scale) for each supplier option, the buying decision becomes far more objective than relying solely on price.

Emerging Trends Relevant for Indian Buyers

Industrial bearings are no longer just commodity items — several trends will affect decisions in the Indian market:

Integrated monitoring sensors. Some modern pillow block units incorporate vibration or temperature sensors, enabling predictive maintenance. This helps Indian plants shift from reactive to proactive maintenance regimes.

Enhanced sealing and lubrication systems. With difficult Indian environments (dust, moisture, heat) new grades of grease, improved labyrinth seals, and even self-lubricating inserts (in smaller applications) are becoming common.

High-capacity and modular housings. Heavy industries (mining, steel, cement) are demanding housings capable of much larger shafts, higher loads, and easier replacement. Split-cap housings and modular insert bearing systems cater to this.

Local manufacturing for global standards. Indian plants increasingly insist on Make-in-India bearing units built to international standards, enjoying both cost advantage and supply-chain resilience.

Digital twin and lifecycle analytics. Some leading suppliers in India now provide digital modelling of bearing life under actual load/temperature cycles, enabling more precise selection upfront and optimised maintenance intervals.

Keeping these trends in mind enables industrial buyers to future-proof their decisions rather than simply matching yesterday’s specification.

Conclusion

The decision process for choosing a pillow block bearing India supplied unit must go well beyond matching bore size and housing footprint. Real industrial value comes from understanding the interacting variables of load, speed, environment, maintenance regime and supplier ecosystem. A well-selected unit protects against unplanned downtime, reduces lifecycle cost and aligns with local maintenance practices.

Purchasing on price alone is risky — instead apply a disciplined checklist covering duty profile, materials, support infrastructure and industrial environmental demands. That way, the bearing unit becomes a robust, long-term contributor to plant reliability rather than a recurring source of failure.

Leave a Reply