Is this okay to say, “Future generation is blessed with technology that will ease their workload and burden of overtime and meet deadlines.” We guess, yes. Because AI, automation and smart tech are working and evolving. These advancements ensure manual burden is reduced and productivity can be increased.

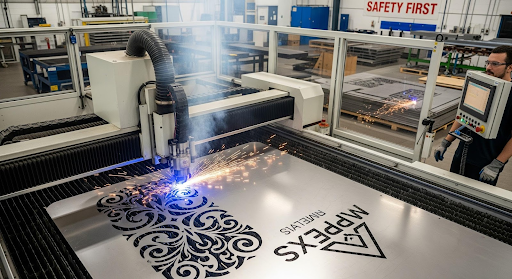

Laser cutting technology is undergoing a transformative shift, driven by the integration of AI. Once considered a traditional manufacturing tool, laser cutting systems are now becoming smart and productive. This evolution is crucial for industries seeking competitiveness, sustainability and faster outcomes. In this increasingly digitalised world, AI has come a long way and will continue to evolve.

Laser Cutting Systems and AI

Several industries, including laser cutting ones, are now understanding how essential it is to evolve with time. AI integration is revolutionising laser cutting in several ways and areas. There is something that one can expect after getting AI for their industry:

- Predictive Maintenance and Downtime Reduction

AI-powered sensors and algorithms can predict when a laser cutter is likely to fail. It allows preemptive maintenance, which can save time and cost. This advantage can minimise downtime, reduce repair costs and increase machine availability.

- Real-Time Quality Monitoring

AI-enabled vision systems can detect material inconsistencies, deviations in cutting paths, and even imperfections in real-time. Machine learning algorithms analyse vast datasets to constantly adjust parameters, resulting in higher quality and less scrap.

Sustainability and material waste reduction are the other benefits that your industry can get. You can work without being much affected by the damages and repairs because real-time data will help sort things.

- Automated Material Handling

AI algorithms automate material sorting, alignment and feed rate adjustments. When combined with robotics and IoT, the entire process becomes seamless and autonomous. From material loading to laser cutting and part sorting, you can achieve these seamlessly with advancements in AI and automation.

- Intelligent Planning

AI optimise cutting paths by analysing material layout, part geometry and thermal effects. It minimises waste, reduces energy consumption and improves throughput. These factors directly benefit profit margins.

Intelligent planning, automated material handling and real-time results, what else can one demand for increasing productivity? If you still have any doubts regarding the laser cutting advancements and smart tech developments, you are on the right track.

Laser Cutting and Advancements: What Are The New Innovations?

In recent years, laser technology has undergone significant changes; these innovations are not just increasing productivity but revolutionising the changes that redefine what laser cutting can achieve. Here are some of the innovations in the field:

- Advancements in Laser Sources

Advancements in laser sources for cutting include more efficient and powerful fibre lasers, the development of ultrafast lasers for precision work with minimal heat-affected zones, and the use of new wavelengths like green lasers for cutting reflective materials.

Hybrid systems are also emerging, combining different laser types for increased versatility. These developments lead to higher precision, faster cutting speeds, better beam quality, and the ability to process a wider range of materials, especially in advanced applications and the electronics industry.

- Improvements in Laser Cutting Speed and Efficiency

Faster speeds, greater accuracy and precision are now becoming more common in industries with the latest improvements in laser cutting. Reduced material waste through sophisticated nesting software, increased versatility across various materials, and lower energy consumption with technologies like fibre lasers are possible.

Key advancements are powerful fibre lasers, AI and automation, advanced nesting software, and optimised cutting parameters, leading to higher productivity, lower costs, and improved sustainability for manufacturers.

- Innovation in Material Compatibility

By improving fibre laser power and efficiency for cutting thick and reflective materials, the latest laser cutting innovations have expanded material capabilities. It enables ultrafast lasers for micromachining with minimal heat and increases versatility to include new materials like composites, ceramics, and organic materials.

Advances in CNC and AI-driven automation further enhance precision and adapt to material inconsistencies, while also expanding design possibilities for intricate, customised products across industries like electronics, medical, and aerospace.

Laser cutting has expanded its way too long in innovations, and traditional methods can now be eliminated or used less to promote sustainability, reduced costs and material optimisation.

Final Thoughts

The future of metal laser cutting in Canada is bright because of the latest advanced technologies. AI, automation and smart technologies are paving the way for the future generation. Industries are adopting these methods and promoting more sustainable results than before. Improved speed, efficiency and material optimisation is guaranteed with these technologies.

Leave a Reply