In today’s fast-moving manufacturing world, speed and precision are the ultimate competitive edges. From golf clubs and aircraft engines to surgical instruments, every industry now relies on rapid prototyping to shorten development cycles and refine designs before full-scale production.

At the forefront of this transformation is Yicen Precision a trusted name in precision engineering that combines cutting-edge CNC machining with advanced rapid prototyping. Their expertise helps manufacturers bring ideas to life quickly, cost-effectively, and with extraordinary accuracy.

Through rapid prototyping CNC services, Yicen empowers engineers to test designs, evaluate functionality, and optimize components across diverse sectors, ensuring every product performs flawlessly when it reaches the market.

Understanding Rapid Prototyping CNC Services

Rapid prototyping is a process that turns digital 3D models into physical parts using precision CNC machining, additive manufacturing, and other techniques. Unlike traditional manufacturing, where creating molds or tools can take weeks, rapid prototyping allows for near-instant fabrication and testing.

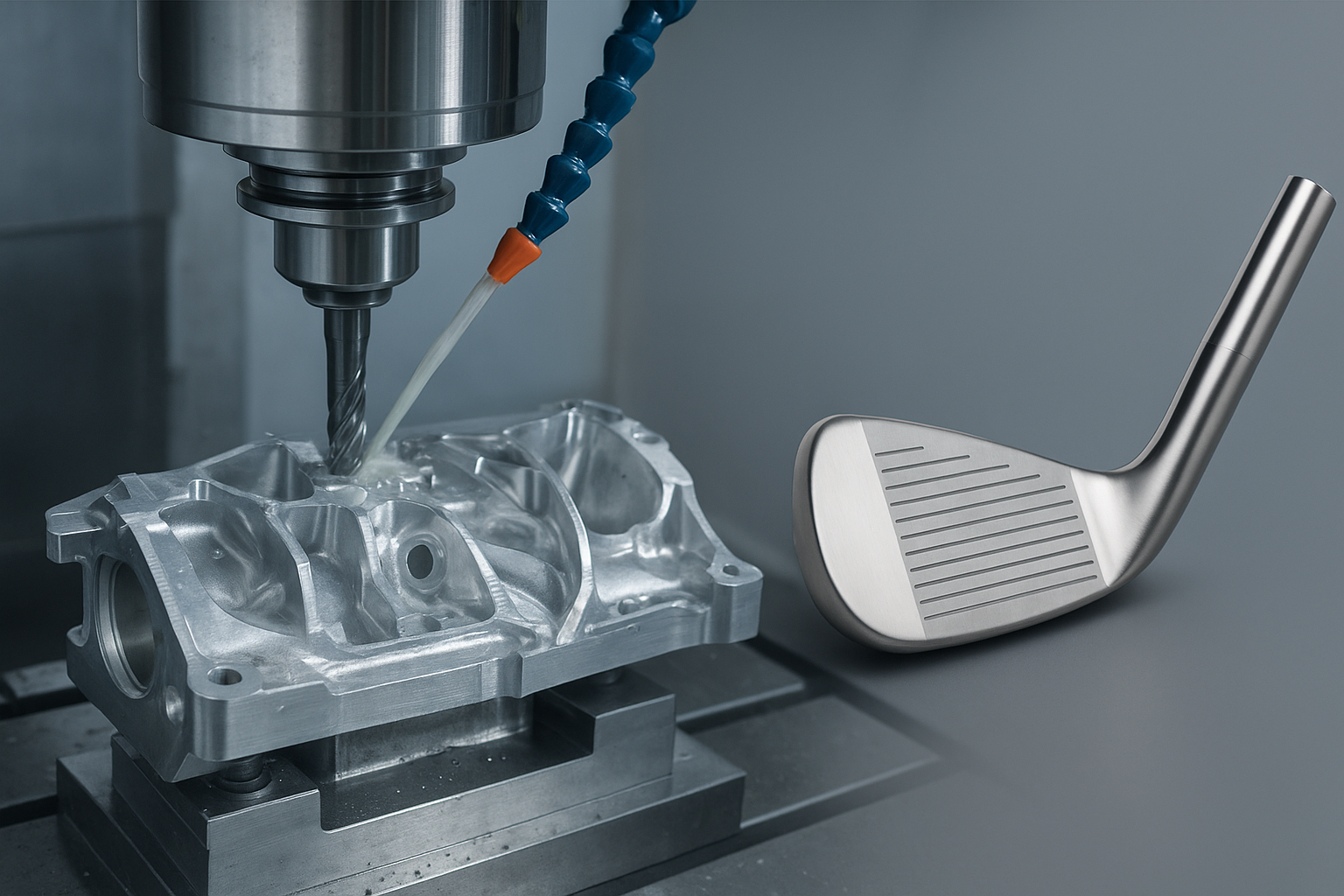

Yicen Precision utilizes advanced 3-axis and 5-axis CNC machines capable of working with aluminum, stainless steel, titanium, and high-performance polymers. This flexibility allows designers to experiment with material properties, surface finishes, and tolerance levels all crucial for industries like aerospace, medical, and sports equipment manufacturing.

The company’s combination of skilled craftsmanship and state-of-the-art automation ensures that every prototype not only looks like the final part but also performs as expected under real-world conditions.

Driving Innovation in Golf Stick Sole Manufacturing

Sports engineering demands balance, precision, and consistency and few areas exemplify that more than the design of a golf stick sole. The shape and weight distribution of a club’s sole directly impact the swing trajectory and overall playability.

By leveraging Yicen’s rapid prototyping CNC services, golf manufacturers can quickly iterate through multiple design variations, adjusting angles, contours, and materials to achieve the perfect balance. CNC machining ensures precise symmetry and smooth finishes, giving prototypes the same feel as final production units.

Yicen’s ability to deliver prototypes with micrometer-level accuracy allows engineers to evaluate aerodynamics and ergonomics before committing to large-scale production. This accelerates innovation and helps manufacturers bring high-performance sports equipment to market faster.

Advancing Aerospace and Vehicle Component Production

In aerospace and automotive manufacturing, precision isn’t optional it’s critical for performance and safety. From turbine blades to engine housings, every part must meet strict dimensional tolerances and withstand extreme operational conditions.

Yicen Precision’s CNC systems achieve ultra-tight tolerances up to ±0.001 mm, ensuring consistent, repeatable results. The company’s advanced inspection systems, CAD/CAM integration, and real-time feedback loops enable faster prototype validation and shorter production lead times.

For vehicle and aircraft manufacturers, this translates into lighter, stronger, and more efficient components. Whether it’s optimizing the aerodynamics of an aircraft bracket or improving the durability of an automotive suspension part, Yicen’s rapid prototyping solutions deliver accuracy and reliability from concept to completion.

Precision Machining for Medical Components

In the medical field, precision saves lives. Every device and implant must meet exact specifications to ensure safety, biocompatibility, and functionality. Yicen Precision applies its deep knowledge of CNC machining to create intricate parts for surgical tools, orthopedic devices, and dental instruments.

By following the principles detailed in Yicen’s CNC part tolerances guide, engineers can design components that fit seamlessly within complex assemblies. High-tolerance machining minimizes friction, misalignment, and assembly errors — critical for medical products that demand consistent quality.

Yicen’s production processes meet stringent international standards and include comprehensive inspection at every stage. Each part is verified through coordinate measuring machines (CMM), surface roughness testing, and optical analysis to guarantee precision and reliability.

The Integration of Rapid Prototyping and CNC Machining

While additive manufacturing technologies like 3D printing are becoming more common, CNC machining remains the gold standard for creating functional prototypes from production-grade materials. Yicen combines both subtractive and additive processes to provide the best of both worlds speed and strength.

Engineers can produce test parts overnight, evaluate performance, make design changes, and re-prototype immediately. This integrated approach accelerates design cycles, minimizes cost overruns, and improves communication between design and manufacturing teams.

Yicen’s flexible production systems can handle one-off prototypes or low-volume production runs, allowing businesses to scale efficiently from testing to manufacturing.

Quality and Consistency as Core Values

At the heart of Yicen Precision’s operations lies an unwavering commitment to quality. Every stage of production from CAD modeling to final inspection is backed by data-driven quality assurance and strict process control.

Their team uses high-resolution digital measurement systems and automated inspection reports to maintain uniformity across batches. This ensures that when a prototype transitions to mass production, there are no deviations in performance or dimension.

Moreover, Yicen’s engineering team collaborates closely with clients to refine designs for manufacturability (DFM), helping reduce costs without compromising precision or performance.

The Future of Manufacturing with Yicen Precision

As industries push toward lightweight materials, digital twins, and AI-driven quality control, Yicen Precision continues to innovate at the forefront of advanced manufacturing. Their expertise in rapid prototyping, combined with decades of CNC machining experience, enables companies to meet growing demands for sustainability, customization, and speed.

From golf equipment to jet engines, from automotive innovations to life-saving medical implants — Yicen delivers the precision, speed, and reliability manufacturers need to succeed in a global market defined by continuous innovation.

Conclusion: Shaping Tomorrow’s Engineering Standards

Precision is not just a requirement it’s the foundation of progress. Through rapid prototyping CNC services, Yicen Precision empowers industries to innovate faster, smarter, and more efficiently. Their ability to turn complex designs into high-performance prototypes and production parts defines the next era of global manufacturing.

With unmatched expertise, quality control, and dedication to excellence, Yicen Precision stands as a trusted partner driving the evolution of aerospace, medical, and sports manufacturing one precise part at a time.

Leave a Reply