In any warehouse, distribution center, or industrial setting, safety is non-negotiable. Forklifts are essential machines in these environments, yet they also rank among the top causes of workplace injuries. One of the most overlooked factors in maintaining forklift safety is the proper selection, use, and upkeep of forklift parts and equipment. When even a minor component fails, it can lead to serious accidents, costly downtime, or damage to property.

This article explores the crucial connection between safety and properly maintained forklift parts and equipment. It also provides guidance on how to choose the right components, conduct preventive maintenance, and ensure compliance with industry safety standards.

Why Forklift Safety Starts with the Right Parts

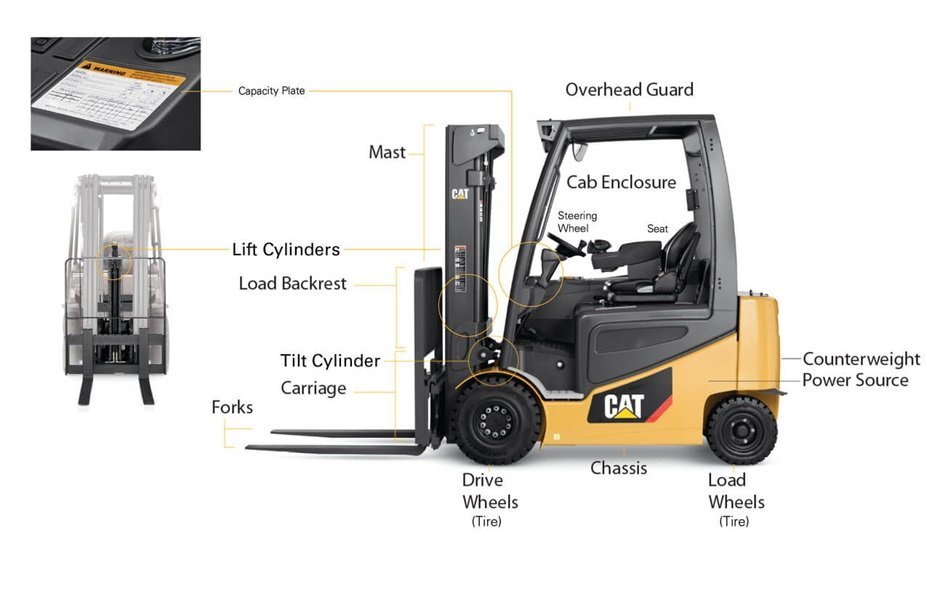

Forklifts are designed to handle heavy loads, navigate tight spaces, and operate in demanding conditions. To do this effectively and safely, every component must function precisely as intended. From tires and brakes to hydraulic hoses and warning lights, each part plays a role in the overall safety of the machine.

When it comes to forklift parts and equipment, using worn, incompatible, or low-quality items can compromise not only performance but also worker safety. Faulty brakes, cracked forks, or malfunctioning alarms can result in accidents that could have easily been prevented with proper upkeep and replacement.

Common Forklift Parts That Impact Safety

Let’s examine the key forklift parts and equipment that directly affect operational safety:

1. Braking System Components

The brake system—comprising brake pads, drums, discs, and hydraulic lines—is critical for controlling the forklift. Worn or damaged brake components reduce stopping power and increase the risk of collisions.

Safety Tip: Inspect brakes weekly. Replace parts that show signs of wear, such as thinning pads or squeaking noises during operation.

2. Forks and Attachments

The forks are responsible for lifting and supporting loads. Over time, they can become bent, cracked, or worn. Attachments such as clamps and rotators must also be checked for functionality and proper mounting.

Safety Tip: Inspect forks for cracks, uneven wear, and alignment. Replace any fork that is worn by more than 10% of its original thickness.

3. Hydraulic Hoses and Cylinders

Hydraulics control the lifting and tilting mechanisms. Leaks, burst hoses, or weakened seals can result in load drops or sudden movements—endangering both operators and nearby workers.

Safety Tip: Monitor hydraulic fluid levels and inspect hoses for leaks, bulges, or abrasions.

4. Tires

Tires provide stability and traction. Improperly inflated or worn tires reduce maneuverability and can lead to tip-overs, especially when carrying heavy or unbalanced loads.

Safety Tip: Regularly check tire pressure and tread depth. Replace tires with cracks, flat spots, or excessive wear.

5. Safety and Warning Systems

These include seatbelts, horns, backup alarms, strobe lights, and mirrors. All are designed to alert the operator and pedestrians to potential hazards.

Safety Tip: Test alarms and lights daily before use. Ensure mirrors are clean and properly adjusted.

Choosing the Right Forklift Parts and Equipment

Not all parts are created equal. Selecting the right forklift parts and equipment means prioritizing quality, compatibility, and compliance with safety standards.

OEM vs. Aftermarket Parts

- OEM (Original Equipment Manufacturer) parts are designed specifically for your forklift make and model. They ensure perfect fit and performance but may come at a premium price.

- Aftermarket parts are usually less expensive but vary widely in quality. Choose reputable suppliers who meet industry safety standards and provide warranty-backed products.

Tip: Always cross-reference part numbers and consult your equipment manual or dealer to ensure compatibility.

Key Equipment Upgrades That Improve Safety

In addition to replacing worn components, consider these upgrades to boost safety further:

- Blue spotlights and rear-view cameras for visibility

- Speed limiters to control forklift velocity

- Load backrests to prevent items from falling backward

- Proximity sensors to detect nearby pedestrians or obstructions

These upgrades can be integrated into your current fleet with minimal downtime and can drastically reduce the risk of accidents.

Preventive Maintenance: The Cornerstone of Safety

Even the best forklift parts and equipment won’t keep your operations safe if they aren’t maintained properly. Preventive maintenance is the key to identifying small issues before they turn into safety hazards.

Develop a Maintenance Schedule

Follow the manufacturer’s guidelines for inspections and servicing. A good schedule should include:

- Daily inspections by operators (fluid levels, lights, tires, forks)

- Weekly checks of brakes, hydraulics, and batteries

- Monthly maintenance with deeper diagnostics by trained technicians

Train Your Operators

Operators should be trained not only to drive the forklift but also to identify potential issues with forklift parts and equipment. Encourage a culture of reporting and immediate action when a part is malfunctioning.

Compliance with OSHA and ANSI Standards

OSHA (Occupational Safety and Health Administration) requires that employers ensure their powered industrial trucks are safe and properly maintained. Regular inspections, proper part replacement, and training are all part of compliance.

ANSI (American National Standards Institute) also sets standards for design and performance of forklift parts and equipment, including load-handling and safety devices.

Failing to follow these standards not only increases accident risk but can also lead to costly violations and legal consequences.

Where to Source Quality Forklift Parts and Equipment

Whether you’re based in Houston, Los Angeles, or anywhere else, finding a reputable supplier is essential. Look for providers who:

- Specialize in forklift parts and accessories

- Offer same-day or expedited delivery

- Provide OEM and high-quality aftermarket options

- Support a wide range of brands (Toyota, Hyster, Yale, Crown, etc.)

- Offer expert guidance on installation and maintenance

Establishing a relationship with a trusted supplier ensures quick access to the parts you need and expert advice to help you stay compliant and safe.

Final Thoughts

Workplace safety depends on many factors, but few are as foundational as the condition of your equipment. Investing in reliable, high-performance forklift parts and equipment isn’t just a cost of doing business—it’s a commitment to safety, productivity, and long-term success.

Leave a Reply