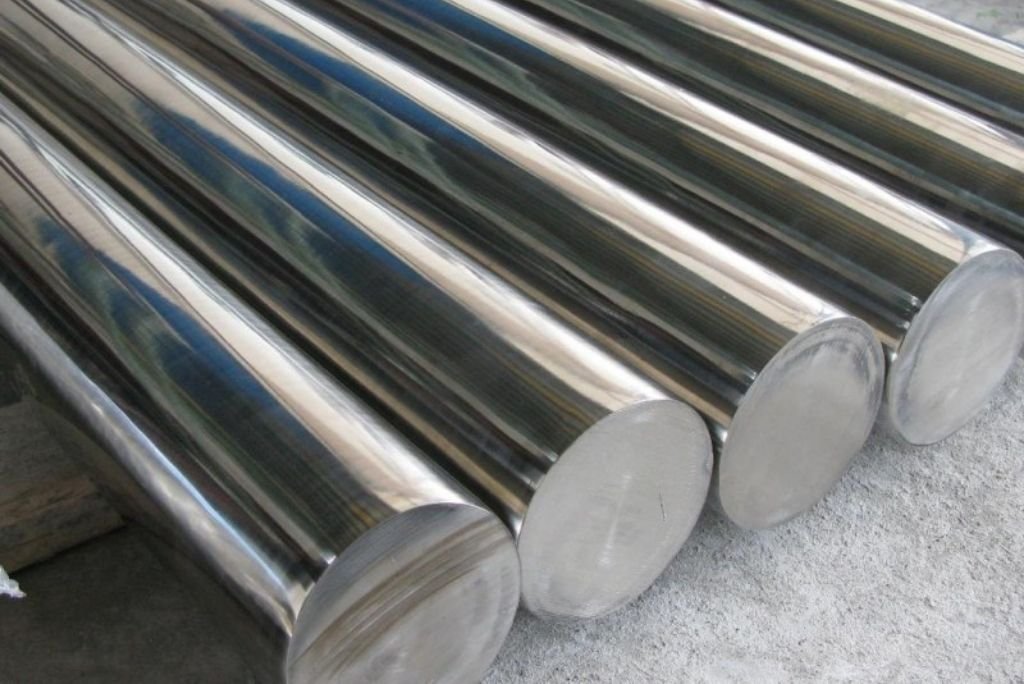

Stainless steel plays a crucial role in modern engineering and industrial applications. Among the many stainless steel grades available, stands out due to its unique combination of strength, corrosion resistance, and versatility. This martensitic stainless steel is widely used across multiple industries where durability and performance are essential. In this blog, we will explore the key advantages of using 431 SS Round Bar and why it remains a preferred choice for various applications.

What is 431 SS Round Bar?

431 stainless steel is a high-chromium martensitic alloy with excellent tensile strength and superior corrosion resistance. It contains approximately 15-17% chromium and 1.25-2.5% nickel, which enhances its mechanical properties and makes it suitable for demanding environments. This alloy is typically supplied in a hardened and tempered condition to maximize its performance capabilities.

Chemical Composition of SS Round Bar:

- Chromium (Cr): 15.0-17.0%

- Nickel (Ni): 1.25-2.5%

- Carbon (C): 0.12-0.20%

- Manganese (Mn): 1.00% max

- Silicon (Si): 1.00% max

- Phosphorus (P): 0.040% max

- Sulfur (S): 0.030% max

Follow for more

Key Advantages of Using 431 SS Round Bar

1. High Strength and Hardness

One of the most notable advantages of 431 SS Round Bar is its exceptional strength and hardness. The alloy can be heat-treated to achieve even higher mechanical properties, making it ideal for applications requiring superior toughness. This feature is particularly valuable in industries where components are subjected to heavy loads and mechanical stress.

Applications Benefiting from High Strength:

- Automotive shafts and gears

- Aerospace components

- Marine propeller shafts

- Fasteners and bolts

2. Excellent Corrosion Resistance

While martensitic stainless steels are generally less resistant to corrosion than austenitic grades, SS Round Bar offers superior resistance compared to other martensitic alloys. Its chromium content provides effective protection against oxidation and mild corrosive environments, including freshwater and atmospheric conditions.

Ideal for Corrosive Environments:

- Marine and coastal applications

- Chemical processing equipment

- Outdoor structural components

3. Superior Wear and Abrasion Resistance

The high hardness of 431 SS Round Bar translates to excellent wear and abrasion resistance. This property is essential in applications where parts are exposed to friction, impact, or mechanical wear over extended periods.

Common Wear-Resistant Applications:

- Bearings and bushings

- Pump shafts and valves

- Mechanical seals

4. Good Heat Resistance

SS Round Bar can retain its strength and mechanical properties at elevated temperatures. This makes it suitable for applications exposed to moderate heat, where maintaining dimensional stability and performance is critical.

Examples of Heat-Resistant Uses:

- Automotive exhaust systems

- Heat exchangers

- High-temperature industrial machinery

5. Machinability and Workability

Although harder than many stainless steels, SS Round Bar offers good machinability when properly annealed or heat-treated. It can be machined using standard practices and is compatible with various cutting tools and techniques.

Applications Requiring Precision Machining:

- Medical instruments

- Precision-engineered components

- Tooling and dies

6. Impact Resistance and Toughness

In addition to its high strength, 431 SS Round Bar exhibits remarkable toughness and impact resistance. This property is especially valuable in applications where mechanical components must endure sudden shocks or dynamic forces without fracturing.

Industries Utilizing Impact-Resistant Materials:

- Aerospace and defense

- Heavy machinery manufacturing

- Oil and gas exploration

7. Versatility Across Industries

The combination of mechanical strength, corrosion resistance, and wear properties makes 431 SS Round Bar highly versatile. It is used across a broad range of industries that require reliable performance in challenging conditions.

Diverse Industry Applications:

- Marine and shipbuilding

- Automotive and aerospace

- Construction and infrastructure

- Medical and food processing equipment

How to Select the Right SS Round Bar

When choosing 431 SS Round Bar for a project, it is important to consider the following factors to ensure optimal performance:

- Size and Diameter: Select the appropriate dimensions to meet your mechanical load and design requirements.

- Heat Treatment Condition: Choose the desired hardness level based on the specific application needs.

- Environmental Conditions: Evaluate the potential for corrosion, temperature exposure, and wear to select the right finish and alloy condition.

Maintenance and Care of SS Round Bar

To extend the lifespan and maintain the performance of 431 SS Round Bar, consider these maintenance practices:

- Regular Inspection: Check for signs of wear, corrosion, or mechanical fatigue.

- Proper Cleaning: Use appropriate cleaning solutions to remove contaminants and prevent surface degradation.

- Lubrication: Apply suitable lubricants in moving parts to reduce friction and enhance wear resistance.

Conclusion

SS Round Bar offers a unique combination of high strength, superior corrosion resistance, and excellent wear properties, making it a valuable material for a wide range of industrial applications. Whether you are involved in the marine, aerospace, automotive, or manufacturing sectors, this alloy provides the durability and reliability needed for demanding environments. By understanding its key advantages and proper maintenance, you can leverage 431 SS Round Bar to improve the performance and longevity of your mechanical systems.

Leave a Reply