In today’s highly competitive manufacturing landscape, industries demand components that combine strength, precision, and long-term reliability. From heavy machinery and automotive assemblies to aerospace structures and industrial tooling, the quality of machined metal parts directly impacts performance, safety, and operational efficiency. This is where an industrial metal milling service plays a vital role. By using advanced milling techniques and robust materials, manufacturers can produce durable machined parts that meet exact specifications and withstand harsh working conditions.

A professional metal milling service is more than just a machining solution—it is a strategic investment in product quality and consistency. Industrial milling ensures tight tolerances, repeatable accuracy, and superior surface finishes, even for complex geometries and high-volume production. This article explores how industrial metal milling services deliver durable machined parts, the technologies behind the process, and the benefits they bring to modern industries.

Understanding Industrial Metal Milling Service and Its Role in Manufacturing

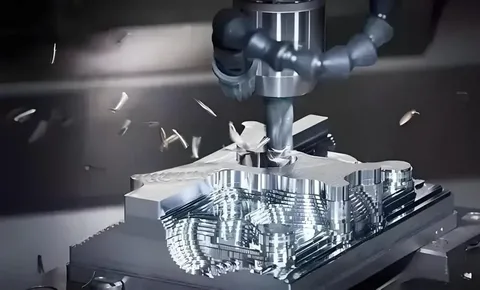

An industrial metal milling service involves the use of rotating cutting tools to remove material from solid metal workpieces, shaping them into precise components. Unlike basic machining methods, industrial milling focuses on high accuracy, scalability, and durability. It is commonly used to manufacture parts for demanding applications such as construction equipment, oil and gas machinery, power generation systems, and aerospace components. Milling machines can operate on multiple axes, enabling the production of intricate shapes and features that would be difficult or impossible with manual processes.

The role of a metal milling service in manufacturing goes beyond shaping metal. It ensures that each part meets strict dimensional and mechanical requirements while maintaining structural integrity. Industrial milling processes are designed to handle hard metals like stainless steel, titanium, aluminum alloys, and tool steels. By applying the correct cutting parameters, tooling, and cooling methods, manufacturers can achieve consistent results while preserving the strength and durability of the material. This makes metal milling an essential process for producing parts that must perform reliably under stress, heat, and continuous use.

Advanced Milling Technologies for Durable Machined Parts

Modern industrial metal milling service providers rely on advanced CNC (Computer Numerical Control) milling technology to achieve superior precision and durability. CNC milling machines are programmed with detailed digital designs that guide cutting tools with extreme accuracy. This technology eliminates human error, ensures repeatability, and allows for complex multi-axis machining. As a result, manufacturers can produce durable parts with tight tolerances, even in large production runs.

In addition to CNC automation, advanced tooling and cutting strategies play a key role in durability. High-performance carbide tools, coated cutters, and optimized tool paths reduce heat buildup and minimize material stress during machining. This helps maintain the mechanical properties of the metal, preventing micro-cracks or weaknesses that could compromise part longevity. By combining modern equipment with experienced operators, a professional metal milling service delivers components that are not only precise but also structurally robust and long-lasting.

Material Selection and Its Impact on Machined Part Durability

The durability of machined components largely depends on the materials used, and a reliable metal milling service understands how to work with a wide range of industrial metals. Common materials include aluminum for lightweight strength, stainless steel for corrosion resistance, carbon steel for toughness, and titanium for high strength-to-weight ratios. Each material requires specific milling techniques to ensure optimal performance without compromising durability.

An experienced metal milling service carefully considers material properties such as hardness, thermal conductivity, and tensile strength when planning the machining process. Proper material selection and handling reduce wear on tools and prevent defects like warping or surface damage. By aligning material choice with application requirements, manufacturers can produce parts that endure heavy loads, extreme temperatures, and corrosive environments. This attention to material detail ensures that the final machined parts maintain their integrity throughout their service life.

Precision, Tolerances, and Quality Control in Metal Milling

Precision and tight tolerances are critical in industrial manufacturing, and a professional metal milling service prioritizes both to ensure durability. Even minor dimensional inaccuracies can lead to premature wear, poor assembly fit, or system failure. Industrial milling operations use high-precision measuring instruments and real-time monitoring systems to maintain exact specifications throughout the machining process.

Quality control is an integral part of any reliable metal milling service. Inspections are conducted at multiple stages, from raw material verification to final part measurement. Techniques such as coordinate measuring machines (CMMs), laser scanning, and surface roughness testing ensure that every component meets industry standards. This rigorous quality assurance process guarantees that machined parts perform consistently, resist fatigue, and deliver long-term reliability in demanding industrial applications.

Applications of Industrial Metal Milling Service Across Industries

An industrial metal milling service supports a wide range of industries that rely on durable machined parts for critical operations. In the automotive sector, metal milling is used to produce engine components, transmission parts, and structural elements that must withstand constant motion and heat. In aerospace, precision-milled parts are essential for maintaining safety, weight efficiency, and aerodynamic performance. Similarly, the construction and heavy machinery industries depend on strong, wear-resistant components produced through advanced milling processes.

Beyond traditional manufacturing, metal milling services also support renewable energy, medical equipment, and industrial automation. Wind turbines, hydraulic systems, and robotic assemblies all require precisely machined metal parts for reliable performance. By offering customized solutions, an industrial metal milling service adapts to the unique requirements of each sector. This versatility makes milling a cornerstone of modern manufacturing, enabling industries to innovate while maintaining durability and operational efficiency.

Benefits of Choosing a Professional Industrial Metal Milling Service

Partnering with a professional metal milling service offers significant advantages for manufacturers seeking durable machined parts. One key benefit is consistency. Industrial milling providers use standardized processes and advanced machinery to ensure uniform quality across all components. This reduces production errors, minimizes waste, and lowers long-term costs. Additionally, outsourcing milling to experienced professionals allows companies to focus on core operations while relying on expert machining capabilities.

Another major benefit is scalability and customization. A reliable metal milling service can handle both small prototype runs and large-scale production without compromising quality. Custom milling solutions enable manufacturers to create specialized components tailored to specific applications. With access to skilled engineers, advanced equipment, and strict quality control, businesses gain durable, high-performance parts that meet exact specifications and industry standards.

Conclusion

Durable machined parts are essential for industries that demand performance, safety, and longevity. An industrial metal milling service provides the precision, material expertise, and advanced technology required to produce high-quality components that stand the test of time. From complex designs to heavy-duty applications, milling ensures that every part meets strict requirements while maintaining structural integrity.

As industries continue to evolve and demand higher standards, the role of a professional metal milling service becomes even more critical. By investing in advanced milling solutions, manufacturers can enhance product durability, improve operational efficiency, and gain a competitive edge. Whether for automotive, aerospace, construction, or industrial equipment, metal milling remains a trusted foundation for producing durable, reliable machined parts.

Leave a Reply