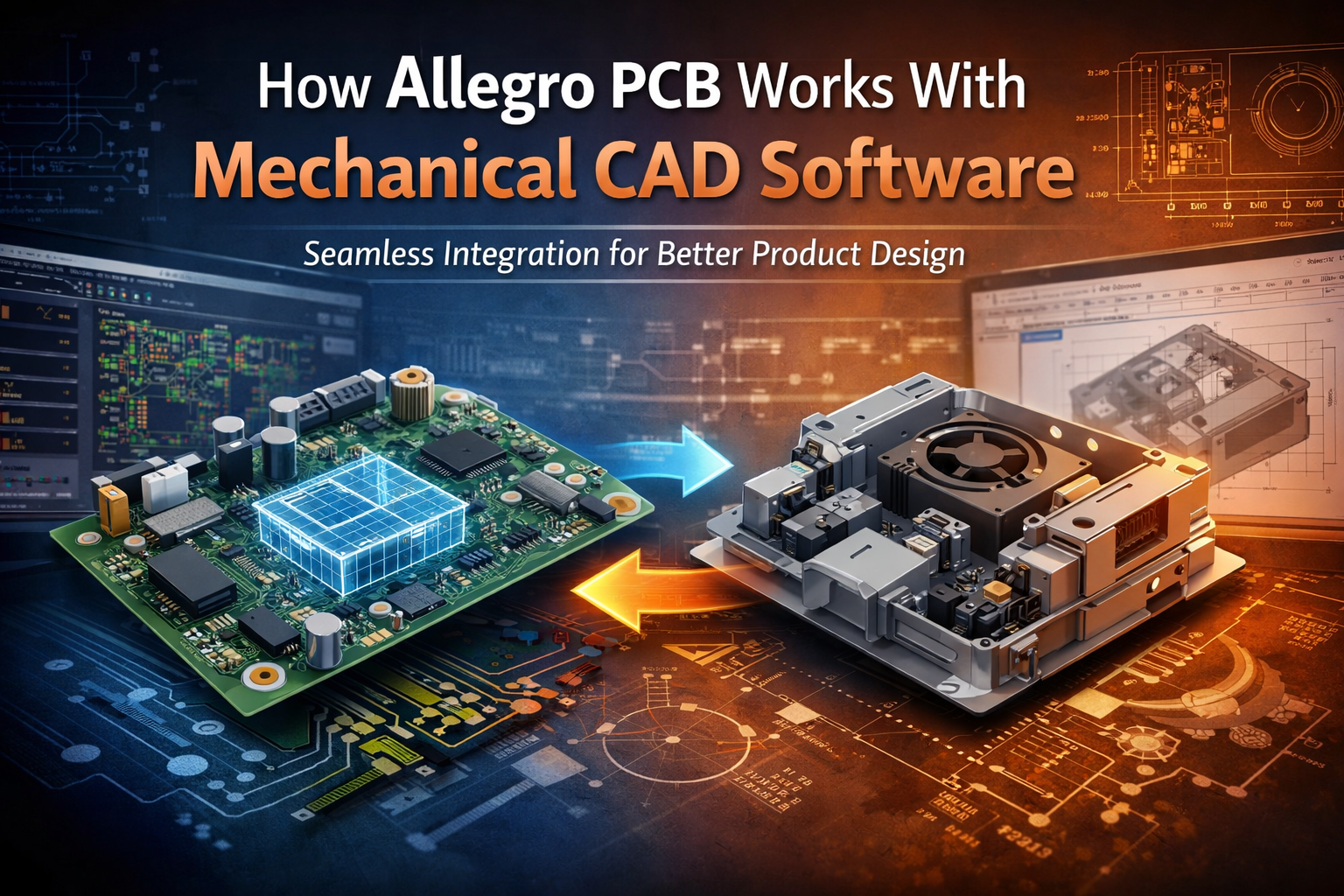

Modern electronic product development is no longer a linear process. Today, electronic and mechanical design teams work side by side to create compact, high-performance, and manufacturable products. In this collaborative environment, Allegro PCB plays an important role by enabling smooth interaction between PCB layout data and mechanical CAD software. This integration helps reduce design errors, shortens development cycles, and improves overall product quality.

In the first stages of PCB design, engineers already consider mechanical constraints such as enclosure size, mounting points, airflow paths, and connector locations. When Allegro PCB data aligns accurately with mechanical CAD systems, teams gain better visibility into how electronic components fit within physical structures. This early coordination is essential for meeting today’s expectations of faster launches and higher reliability.

Why PCB and Mechanical CAD Collaboration Matters

Electronic designs do not exist in isolation. Every printed circuit board must eventually fit into a physical product, whether it is a consumer device, industrial system, or embedded application. Mechanical CAD software defines the product’s housing, structure, and spatial limitations, while PCB tools define electrical connectivity and component placement.

When these two design worlds remain disconnected, problems often surface late in the development cycle. Common issues include component clashes, misaligned connectors, insufficient clearance, and thermal challenges. By enabling effective collaboration between PCB layout data and mechanical models, Allegro PCB helps teams address these risks early, saving both time and cost.

Understanding the Integration Workflow

The integration between PCB design and mechanical CAD typically follows a bidirectional workflow. PCB designers create board layouts with accurate dimensions, layer stack-ups, and component heights. Mechanical designers, in turn, use this data to verify fit, clearance, and enclosure compatibility.

Allegro PCB supports standardized data exchange formats that allow mechanical CAD systems to interpret PCB geometry correctly. This shared data includes board outlines, mounting holes, keep-out zones, and 3D component representations. Once imported into mechanical environments, designers can simulate real-world conditions and provide feedback that feeds back into the PCB layout.

Role of 3D Visualization in Design Accuracy

One of the biggest advantages of PCB and mechanical CAD integration is enhanced 3D visualization. Instead of relying on 2D drawings, teams can view a realistic representation of the assembled board within its enclosure. This clarity makes it easier to detect interference issues, verify connector alignment, and assess accessibility for assembly or maintenance.

Allegro PCB enables designers to generate accurate 3D representations of boards and components. These models improve communication between disciplines and help stakeholders understand design decisions without extensive technical explanations. Visual clarity also supports faster reviews and approvals.

Reducing Design Iterations and Rework

Late-stage design changes are costly. Even minor adjustments to PCB layouts can impact manufacturing timelines and budgets. By synchronizing PCB data with mechanical CAD systems early, teams can reduce the number of design iterations required.

Mechanical feedback related to spacing, structural support, or thermal considerations can be incorporated during initial layout phases. This proactive approach minimizes rework and ensures that both electrical and mechanical requirements are met before prototypes are built.

Thermal and Structural Considerations

Thermal management is a critical factor in modern electronics. Mechanical CAD software often evaluates airflow paths, heat dissipation, and material properties. When PCB layout data from Allegro PCB integrates into these analyses, designers can identify hotspots and optimize component placement accordingly.

Structural integrity is another key area where integration adds value. Mechanical teams can assess whether the PCB has adequate support, whether mounting locations are optimal, and whether vibrations or external forces may affect reliability. These insights contribute to more robust and durable designs.

Mid-Design Validation Through Integrated Reviews

A major benefit of integrating Allegro PCB with mechanical CAD tools is the ability to conduct mid-design validation reviews. Instead of waiting until final layouts are complete, teams can review progress collaboratively.

During these reviews, both electrical and mechanical perspectives are considered simultaneously. This reduces miscommunication and ensures alignment across teams. For deeper insight into how this integration works in practice, you can explore this detailed explanation on how Allegro PCB integrates with mechanical CAD tools, which fits naturally into this design collaboration process.

Supporting Manufacturing and Assembly Planning

Beyond design validation, PCB and mechanical CAD integration also supports manufacturing planning. Accurate alignment between board layouts and enclosures helps ensure that automated assembly processes run smoothly. Pick-and-place machines, soldering processes, and final assembly steps all benefit from precise design data.

Allegro PCB data shared with mechanical systems improves predictability during manufacturing. This reduces the risk of production delays caused by unforeseen fitment issues or assembly constraints.

Enhancing Cross-Team Communication

Design projects often involve multiple stakeholders, including electrical engineers, mechanical designers, manufacturing specialists, and quality teams. A shared understanding of the product design is essential for success.

Integrated PCB and mechanical CAD workflows improve communication by providing a single source of truth. Instead of exchanging static drawings or lengthy documentation, teams can collaborate around shared digital models. This transparency aligns everyone around the same design intent.

Aligning With Current SEO and Content Quality Trends

From an industry content perspective, discussions around Allegro PCB and mechanical CAD integration reflect broader trends in digital engineering and collaborative workflows. Search engines in 2025 prioritize content that demonstrates real-world relevance, practical value, and clear explanations.

High-quality technical content focuses on user intent rather than promotional messaging. By explaining how PCB and mechanical integration improves efficiency, accuracy, and product quality, content aligns with modern SEO expectations. Natural keyword placement, logical structure, and informative depth all contribute to stronger visibility and trust.

Data Consistency and Version Control

Another advantage of PCB and mechanical CAD integration is improved data consistency. Design changes occur frequently, and managing versions across teams can be challenging. Integrated workflows help ensure that updates to board layouts or mechanical models are reflected accurately across systems.

This consistency reduces confusion and prevents teams from working with outdated information. It also supports better traceability, which is increasingly important for compliance and quality assurance processes.

Future-Ready Design Practices

As products become smaller, smarter, and more complex, the need for seamless design collaboration will only increase. Allegro PCB’s ability to work alongside mechanical CAD software supports future-ready design practices that emphasize speed, accuracy, and cross-disciplinary alignment.

Design teams that adopt integrated workflows are better positioned to handle evolving requirements, tighter tolerances, and faster innovation cycles. These practices also align with sustainability goals by reducing wasted materials and unnecessary prototypes.

Conclusion

Understanding how Allegro PCB works with mechanical CAD software highlights the importance of integrated design workflows in modern electronics development. By enabling accurate data exchange, 3D visualization, and early validation, this collaboration reduces errors, improves efficiency, and supports higher-quality outcomes.

From concept to manufacturing, the integration of PCB layout data with mechanical models ensures that electronic designs align seamlessly with physical realities. As industry expectations continue to evolve, this approach remains a cornerstone of effective and future-focused product development.

Leave a Reply