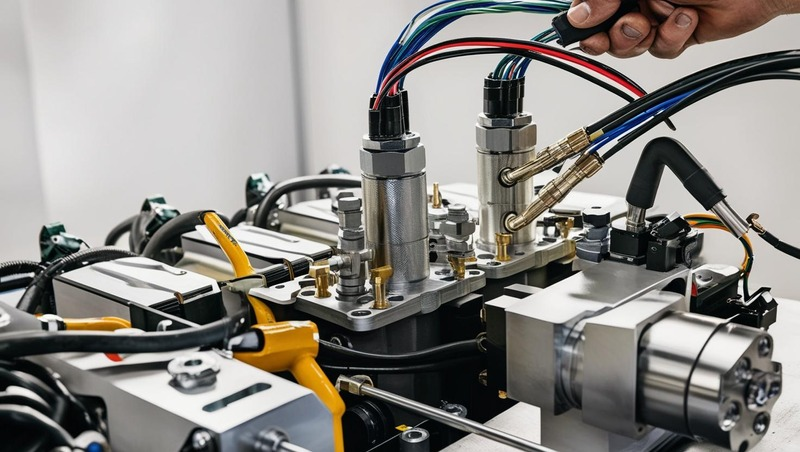

Electro-hydraulic systems combine the power of hydraulics with the precision of electronic controls, making them indispensable in modern industrial machinery, mobile equipment, and automation. These systems provide smooth, responsive, and highly controllable movements by integrating hydraulic power units with electronic sensors, actuators, and controllers.

Because of their complexity, maintaining electro-hydraulic systems requires vigilance. Undetected issues can cause reduced performance, costly downtime, or even hazardous failures. Recognizing the signs that your electro-hydraulic system needs repair is crucial for maintaining efficiency and safety.

This article explores the key indicators that signal electro-hydraulic system repair is necessary, helping you to act promptly and prevent severe consequences.

Understanding Electro-Hydraulic Systems

Electro-hydraulic systems rely on an interplay between hydraulic components and electronic controls. The hydraulic part consists of pumps, valves, cylinders, and motors that generate and transmit force using pressurized fluid. The electronic components—such as sensors, programmable logic controllers (PLCs), and variable frequency drives (VFDs)—monitor and adjust the system’s operation for accuracy and repeatability.

This sophisticated integration allows for precise speed, force, and positioning control in applications ranging from construction equipment and aircraft control surfaces to industrial presses and robotics.

Due to their hybrid nature, electro-hydraulic systems can experience faults in either the hydraulic or electronic subsystems, or both, making troubleshooting and repair a specialized task.

Why Timely Electro-Hydraulic System Repair Is Essential

Electro-hydraulic systems are often critical to core operations. Any malfunction can disrupt production, increase maintenance costs, and pose safety risks. Timely repair ensures:

- Restoration of operational efficiency

- Prevention of secondary damage to related components

- Compliance with safety and quality standards

- Minimization of unplanned downtime and associated costs

Ignoring early warning signs can lead to catastrophic failures, endangering operators and damaging expensive equipment.

Common Signs Indicating Electro-Hydraulic System Repair Is Needed

Recognizing the symptoms of an impaired electro-hydraulic system enables proactive intervention. Below are the most common and telling signs:

Reduced System Performance and Responsiveness

One of the earliest indications of system issues is a decline in performance. If your electro-hydraulic system becomes sluggish, jerky, or unresponsive, this often signals underlying problems. Causes include:

- Hydraulic fluid contamination or degradation

- Malfunctioning electronic sensors or controllers

- Worn hydraulic seals or valves causing internal leakage

This degradation results in slower actuator movements, inconsistent speed control, or failure to reach desired positions, all of which require professional diagnostics and repair.

Unusual Noises and Vibrations

Electro-hydraulic systems are designed to operate smoothly. Grinding, knocking, or whining noises can indicate mechanical wear, cavitation in the pump, misaligned components, or failing motors. Additionally, excessive vibrations often point to worn bearings or imbalance in the hydraulic or electric components.

Ignoring these auditory and tactile cues can accelerate damage, making timely repairs crucial.

Hydraulic Fluid Leaks and Contamination

Leaks are among the most visible signs of hydraulic system trouble. Fluid escaping from seals, hoses, or fittings not only reduces system pressure and efficiency but also risks component damage due to insufficient lubrication.

Contaminated fluid, which may contain water, dirt, or metal particles, compromises valve and actuator performance and increases wear rates. Regular fluid inspection and repair of leaks are vital to maintaining system health.

Electrical System Faults and Errors

The electronic control subsystem is prone to faults that manifest as error codes, warning lights, or complete system shutdowns. Common issues include sensor failure, wiring faults, or software glitches in controllers.

Intermittent or persistent electrical faults can cause erratic system behavior, such as unexpected movements or failure to respond to operator commands. These issues require skilled troubleshooting and repair to restore system integrity.

Overheating of Components

Excessive heat generation in pumps, motors, or control units often signals inefficiency or impending failure. Overheating can result from hydraulic fluid degradation, blocked filters, electrical overloads, or mechanical binding.

If left unaddressed, heat can damage seals, electronic circuits, and mechanical parts, leading to costly repairs or replacements. Prompt identification and repair of overheating causes protect system longevity.

Inconsistent Pressure and Flow Rates

Electro-hydraulic systems rely on stable pressure and flow for consistent operation. Pressure fluctuations, drops, or spikes often indicate internal leaks, clogged filters, faulty pumps, or malfunctioning valves.

Such inconsistencies reduce precision and can cause unpredictable equipment behavior, compromising both productivity and safety. Diagnosing and repairing pressure and flow issues is a clear sign of professional intervention.

Failure to Achieve or Maintain Position

In applications requiring precise positioning—such as robotic arms, machine tools, or aerospace controls—the inability of actuators to reach or hold target positions signals a malfunction.

This failure can stem from hydraulic leaks, control valve defects, sensor errors, or controller malfunctions. Repair is essential to restore accuracy and prevent operational disruptions.

Sudden Loss of Power or Complete System Shutdown

A sudden power loss or emergency stop of an electro-hydraulic system is a critical sign that demands immediate attention. Electrical failures, pump breakdowns, or severe hydraulic faults can cause abrupt shutdowns.

These events not only halt operations but may also indicate hazardous conditions. Rapid diagnostic and repair response is required to resume safe operation.

Visual Damage or Wear on System Components

Routine visual inspections often reveal cracks, corrosion, worn seals, or damaged wiring, which are precursors to system failure. Early detection through maintenance checks can trigger timely repairs before problems escalate.

Professional repair services include thorough component assessment and replacement of damaged parts to restore system integrity.

How Professional Repair Services Address Electro-Hydraulic Issues

Given the complexity of electro-hydraulic systems, professional repair services follow systematic procedures, including:

- Comprehensive diagnostics using pressure gauges, electronic analyzers, and software tools

- Hydraulic fluid analysis and contamination testing

- Component disassembly and inspection for wear or damage

- Replacement of faulty hydraulic seals, valves, hoses, pumps, or electronic sensors

- Calibration and testing of control systems to ensure precision

- System flushing and fluid replacement to restore optimal operation

- Final performance testing under load conditions to verify repair success

These services restore both hydraulic and electronic subsystems to full functionality, ensuring reliability and safety.

Preventive Measures to Minimize Electro-Hydraulic Repairs

In addition to prompt repairs, adopting preventive maintenance practices reduces system failures:

- Regularly check and replace hydraulic fluid and filters

- Conduct scheduled inspections for leaks, noise, and vibrations

- Test electronic controls and sensor calibration periodically

- Maintain clean operating environments to prevent contamination

- Train operators on proper system usage and emergency procedures

A combined approach of preventive care and timely repair maximizes system uptime and extends service life.

The Cost of Delaying Electro-Hydraulic System Repair

Postponing necessary repairs can lead to:

- Increased wear and cascading failures in connected components

- Prolonged downtime with costly production losses

- Safety incidents risking personnel and equipment

- Higher repair costs or full system replacements

Early repair interventions are cost-effective, protect assets, and maintain operational continuity.

Conclusion

Electro-hydraulic systems are complex and vital to modern industrial and mobile machinery. Recognizing the signs that indicate repair needs—such as reduced performance, unusual noises, hydraulic leaks, electrical faults, overheating, inconsistent pressure, positioning errors, or sudden shutdowns—can prevent severe damage and safety hazards.

Professional repair services equipped with specialized diagnostic tools and expertise are essential to restore full functionality and ensure system safety. Complementing repairs with preventive maintenance strategies further prolongs system life and reduces operational risks.

Timely attention to electro-hydraulic system repair safeguards your equipment investment, enhances productivity, and protects your workforce.

For more insightful articles related to this topic, feel free to visit techners.net

Leave a Reply