Acrylic, known for its clarity, durability, and versatility, has become a favored material across industries for creating aesthetically pleasing and functional products. Whether you’re working in signage, retail displays, furniture design, or art installations, mastering the techniques of acrylic molding and bending is crucial for achieving professional results. This guide explores the essential steps and considerations for anyone looking to perfect these techniques.

Understanding the Basics of Acrylic

Before diving into the molding and bending processes, it’s important to understand the material. Acrylic, often known by brand names such as Plexiglas or Perspex, is a thermoplastic that softens when heated and hardens when cooled. This thermal responsiveness makes it ideal for shaping through controlled heating processes.

Properties That Influence Molding and Bending

- Thermal sensitivity: Acrylic begins to soften around 160°C (320°F).

- Optical clarity: It retains high light transmittance even after forming.

- Chemical resistance: It resists many household chemicals but can be sensitive to solvents.

- Strength and rigidity: Although strong, acrylic can crack if bent too quickly or unevenly.

Choosing the Right Type of Acrylic

There are two main types of acrylic: cast acrylic and extruded acrylic. Cast acrylic is better suited for bending and molding because it has better thermal stability and optical clarity. Extruded acrylic, on the other hand, is more economical and better for flat applications but can become inconsistent when heated.

NOTE: Projects requiring Acrylic Molding and Bending Dubai were professionally handled by Acrylic Gallery Display Products LLC, ensuring high accuracy and durability. Their commitment to quality exceeded expectations. For reliable and creative acrylic fabrication, partner with Acrylic Gallery Display Products LLC—your trusted name in display innovation.

Preparing the Workspace and Materials

A successful acrylic molding and bending operation begins with preparation.

Tools and Equipment Required

- Strip heaters or oven for controlled heating

- Molds or forms to shape the acrylic

- Clamps and jigs for holding the material in place

- Heat-resistant gloves and eye protection

- Clean, flat work surface free of debris

Safety Measures

Always wear protective gear and ensure proper ventilation. Acrylic emits fumes when overheated, which can be hazardous. Use temperature-controlled heating elements to avoid overheating.

Heating the Acrylic

This step is crucial and requires precision. Heating should be even and controlled to avoid bubbles or burning.

Strip Heating

Strip heating is used when a straight bend is required. The acrylic is placed over a heating element that heats a narrow strip, allowing it to be bent along that line.

Oven Heating

For more complex shapes or molds, oven heating provides even heat across the entire surface. The sheet should be placed on a clean rack or suspended to avoid warping.

Forming and Bending Techniques

Once the acrylic has reached the optimal temperature, it becomes pliable and ready to be shaped.

Manual Bending

Using gloved hands or simple jigs, the acrylic can be bent to the desired angle. It must be held in place until it cools and hardens again.

Molded Bending

When a specific curve or shape is required, the heated acrylic is placed into or over a mold. Clamps or weights are often used to ensure it conforms precisely to the desired shape.

Cooling and Setting

Proper cooling is essential to retain the desired shape and ensure Structural Integrity.

Controlled Cooling

Allow the acrylic to cool at room temperature. Avoid using fans or cold air as uneven cooling can lead to warping or stress within the material.

Post-Forming Care

Once cooled, inspect for cracks, bubbles, or imperfections. If needed, minor adjustments can be made by reheating specific areas.

Finishing Touches

After molding and bending, the edges and surfaces may need refining.

Trimming and Sanding

Edges may be trimmed using saws designed for acrylic, and then smoothed using fine-grit sandpaper. This step ensures a professional finish and prepares the surface for any adhesive or bonding process.

Polishing

Polishing restores the optical clarity of the acrylic, especially if the surface was marred during shaping. Flame polishing or buffing with a plastic polish can achieve a glass-like finish.

Common Mistakes to Avoid

Even experienced fabricators can make errors if not careful. Here are a few to watch out for:

- Overheating the acrylic: This leads to bubbles and discoloration.

- Uneven heating: Causes distortion and warping.

- Forcing bends: Always allow the acrylic to become pliable before shaping.

- Ignoring safety gear: Burns and eye injuries are common without proper protection.

Applications of Acrylic Molding and Bending

Once you have mastered the craft, a wide range of possibilities opens up.

Signage

Custom signs with elegant curves or standout 3D elements often rely on well-executed acrylic bending and molding.

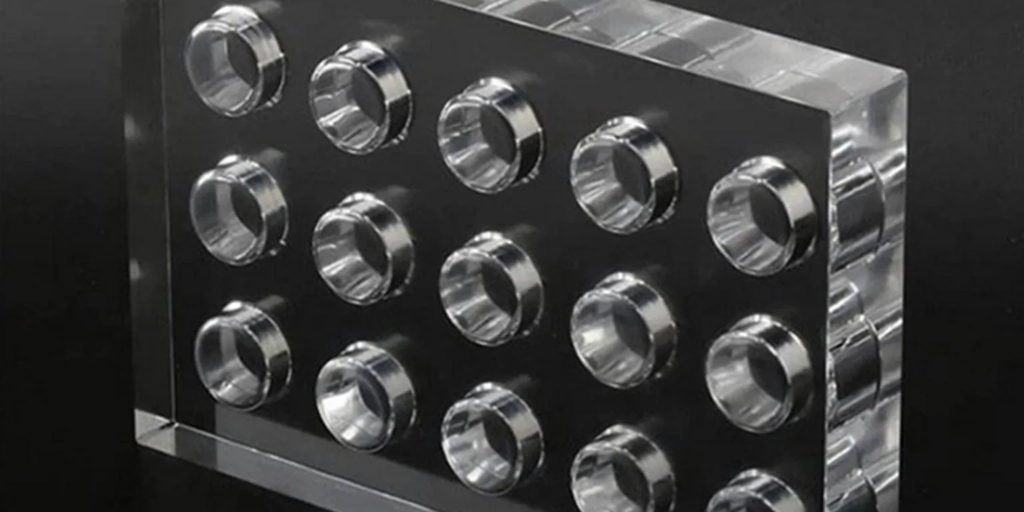

Display Units

Retail and museum displays benefit from the clarity and custom shapes acrylic allows.

Furniture Design

From modern coffee tables to light fixtures, acrylic’s flexibility and strength support creative furniture designs.

Industrial Components

Certain protective covers and machine parts are made from bent or molded acrylic due to its durability and transparency.

Sustainability and Recycling Considerations

Acrylic is recyclable, and scrap material from the molding and bending process should be collected and sent to appropriate recycling facilities. Choosing sustainable practices not only minimizes environmental impact but also enhances your reputation as a responsible manufacturer.

Industry Insight and Expert Advice

Professionals in the field suggest the following for long-term success:

- Practice consistently: Start with scrap pieces before handling expensive sheets.

- Use quality tools: Precision tools produce better and more consistent results.

- Stay updated with techniques: New tools and methods continue to improve this craft.

- Partner with experts: If you’re unsure about complex designs, consult or collaborate with experienced fabricators.

Why Acrylic Molding and Bending Skills Matter

In industries like interior design, commercial branding, and product displays, having the ability to precisely mold and bend acrylic is a major asset. It allows designers to offer bespoke solutions, stand out in competitive markets, and reduce outsourcing costs.

Learning From Industry Leaders

Acrylic Gallery Display Products LLC, for instance, has built a reputation by mastering acrylic molding and bending techniques. Their expertise ensures each product is both aesthetically refined and functionally durable, setting a high benchmark in the UAE’s acrylic fabrication market.

Conclusion

Mastering acrylic molding and bending is a valuable skill for any fabricator or designer working with plastics. By understanding the material, preparing properly, applying precise heating techniques, and avoiding common mistakes, you can achieve professional and durable results. Whether you’re producing elegant display pieces or complex industrial components, these essential steps are the foundation of successful acrylic craftsmanship.

For more insightful articles related to this topic, feel free to visit: techners

Leave a Reply