Turning a unique idea or digital blueprint into a physical product requires a precise and well-managed process. Businesses often rely on the expertise of Chinese manufacturers to produce high-quality plastic injection molding products.

So to explain the entire journey of custom manufacturing, this guide will start with the initial design phase. It covers mold design, part testing, and final mass production in a clear, step-by-step format. The goal is a finished product that meets every one of your specific design requirements.

What Defines Custom Injection Molding?

Custom injection molding is an industrial service that manufactures one-of-a-kind parts according to the demands of a customer. Unlike off-the-shelf components, custom parts have unique shapes, complex features, or special material requirements. The mold tool is built just for that one design, ensuring the finished product is exactly what the designer imagined. This method is used across many industries, including medical, automotive, and consumer electronics.

The Need for Part Customization

Companies use custom molding when standard parts do not fit the final product design. This need for unique parts often involves complicated geometries, snap-fit features, or very tight dimensional tolerances. Customization allows engineers to build specific functions into the part, simplifying final assembly and improving product performance. A custom tool lets designers match the physical part to the exact specifications of the original CAD file.

Choosing the Right Material

Material selection is a major part of the custom process. The required material must meet the product’s needs for strength, heat resistance, and flexibility. Common resins include ABS for strength, Polypropylene (PP) for chemical resistance, and Polycarbonate (PC) for clarity and toughness. Working with an experienced Chinese manufacturer helps you find the best resin that works for both the product’s function and your overall budget goals. The material chosen affects the mold design and the production settings.

Why Choose China for Custom Production?

Globally, China remains a preferred location for many companies needing to manufacture custom parts at a large scale. This preference comes from the combination of manufacturing capacity, established technical skill, and a competitive cost structure. And of course, Chinese factories have decades of experience making complex parts for global markets.

Cost and Scale Advantages

The whole cost of building a custom mold tool is often much lower in China than in Western countries. This affordability is important because the mold tool is the single largest upfront investment in the project.

What’s more, Chinese factories offer an ability to scale production that few other regions can match. They can easily move from small prototype runs to massive orders of millions of units without problems. This scale capability gives businesses flexibility as their product finds market success.

Expertise in Advanced Tooling

Chinese manufacturers have access to highly skilled tooling engineers and advanced equipment. These engineers know how to design tools that produce complex parts while keeping cycle times fast. They use modern software and machinery to build molds that deliver very tight tolerances and consistent quality. This depth of expertise helps reduce the risk of mold failure and long-term maintenance costs.

Integrated Supply Chain

China’s manufacturing centers have a closely connected network of suppliers and service providers. Resin suppliers, tooling shops, and surface finishing companies are often located within a short distance of the molding factory. This close grouping of resources speeds up the entire production timeline. It also reduces the time needed to source materials and complete secondary operations like painting or plating.

How the Custom Process Works

Step 1: Design Review and Optimization

The process starts when the manufacturer’s engineering team performs a Design for Manufacturability (DFM) review on the part file. This review looks for any part of the design that could cause defects during molding. Engineers will suggest changes to wall thickness, corner radii, or part structure to make the part easier to mold. This work helps prevent costly mold modifications later on.

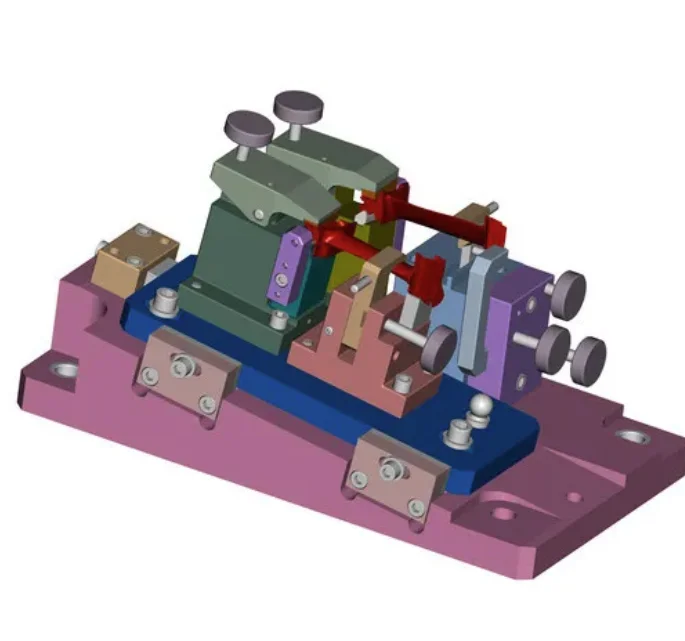

Step 2: Tooling Design and Fabrication

After the design is approved, work begins on the mold tool itself. The mold is designed to handle the selected plastic resin and the required production volume. For high-volume projects needing millions of cycles, the manufacturer will build a hardened steel tool. For lower volume runs or parts still in the testing phase, they may build a softer steel or aluminum tool because it is faster and costs less money. Precision fabrication of the mold is paramount to the quality of the finished part.

Step 3: Prototyping and Testing

Once the mold is complete, the factory runs a test batch of parts in a process called First Article Inspection (FAI). These initial parts are carefully checked against the original blueprints for dimensional accuracy and fit. The parts are often tested for physical function, such as how well they assemble with other components. This prototyping phase confirms the tool works correctly before the manufacturer commits to a full production run.

Step 4: Process Validation and Automation

With the mold and the part design verified, the manufacturing process is validated. This means the machine parameters (e.g., injection speed, temperature, and pressure) are set and locked. Manufacturers use monitoring systems to confirm that every production cycle follows these set parameters. This validation step is needed to maintain consistency and repeatability across thousands or millions of production cycles.

Step 5: Final Quality Inspection

The final step involves a thorough quality check of the finished components. Inspectors use advanced tools like Coordinate Measuring Machines (CMM) and optical scanners to verify the part’s size and shape. They also perform a visual check for cosmetic flaws such as flash, short shots, or burn marks. Only parts that pass all dimensional and aesthetic standards are approved for packaging and shipping to the customer.

Key Takeaway

Making custom parts requires technical skill and a well-managed system. So partnering with a skilled supplier gives you access to the advanced methods needed to make accurate plastic injection molding products. This way, you gain competitive cost, high production speed, and quality management throughout the entire manufacturing process.

Leave a Reply