Same-day delivery promises, volatile fuel prices, and unpredictable disruptions have turned routing into one of the most powerful levers in modern supply chains. A poorly planned route means late deliveries, excess miles, overtime costs, and frustrated customers. A smart route can do the opposite: cut emissions, control costs, and delight end customers with accurate ETAs.

For years, routing depended on static plans, driver experience, and yesterday’s data. But supply chains now move in real time. Traffic patterns shift by the minute, orders are revised on the fly, and capacity constraints change throughout the day. Traditional tools simply cannot keep up with that level of volatility.

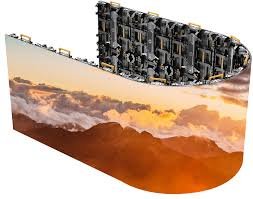

This is where Internet of Things (IoT) data streams fundamentally change the game. Connected trucks, trailers, pallets, and even loading bays now produce a continuous flow of information about location, conditions, and performance. When this data feeds routing engines and operational systems, logistics teams can make decisions that are not just faster, but smarter and more precise than ever before.

From static routes to dynamic, data-driven logistics

Classic route planning tools work in batch mode. Planners generate routes once—often the night before—based on order volumes, service windows, and historical drive-time assumptions. Drivers may tweak these routes on the road, but the plan itself does not adapt to what actually happens during the day.

IoT-enabled routing treats the network as a live system. Sensors embedded in vehicles, trailers, and infrastructure send telemetry in real time: GPS coordinates every few seconds, engine health metrics, congestion alerts, and more. This creates a living picture of the network that updates continuously.

With streaming data, routing is no longer a one-time calculation. Algorithms can re-evaluate the plan whenever new information appears: a major accident, a sudden weather event, an urgent order from a key customer, or an unexpected delay at a loading bay. Modern fleet and telematics platforms already combine IoT and analytics to dynamically re-route vehicles, refine ETAs, and cut idle time for drivers and assets.

Even small percentage improvements in miles or time per route can translate into major savings at scale, especially for large fleets executing thousands of stops per day.

The IoT data streams that matter most for routing

Not every data point is equally useful. The key is to focus on the IoT streams that directly influence routing decisions and service quality.

1. Location and telematics data from vehicles

The foundation is still GPS location—but modern telematics devices provide far more:

- Speed and acceleration patterns

- Harsh braking and idling events

- Fuel consumption and remaining driving hours

- Engine health and diagnostic codes

Integrating this data into routing and dispatch systems enables:

- More accurate ETAs, based on real driving speeds rather than static averages.

- Dynamic re-routing when a truck is falling behind schedule.

- Driver coaching, helping reduce risky behavior and fuel waste.

Connected-fleet platforms that combine IoT sensors and onboard diagnostics now deliver real-time visibility and optimized routing as standard capabilities.

2. Shipment and asset condition monitoring

IoT tags and sensors attached to pallets, containers, and trailers provide continuous insight into where goods are and what condition they are in. Temperature, humidity, shock, and door sensors are especially critical in food, pharma, and other high-value or sensitive supply chains.

When a sensor detects that:

- A trailer’s internal temperature is drifting out of range, or

- A door has been opened unexpectedly, or

- A pallet has experienced a severe impact

…the routing system can respond. It might divert the vehicle to the nearest compliant facility, prioritize a particular stop, or alert quality and security teams. Routing becomes a tool not just for cost optimization, but also for protecting product integrity and mitigating risk.

3. Traffic, weather, and infrastructure feeds

Some of the most powerful influences on routing come from outside the company’s own assets:

- Live traffic and congestion data

- Incident and road-closure reports

- Weather alerts and forecasts

By feeding these external streams into routing engines, logistics teams can avoid known bottlenecks, plan around storms, and steer drivers toward safer or more predictable roads. Studies on IoT-enabled logistics show that combining vehicle telematics with contextual data such as traffic and weather yields some of the largest gains in routing reliability and efficiency.

4. Warehouse, yard, and loading-bay signals

IoT doesn’t stop at the truck. Sensors at gates, docks, and staging areas can track:

- Queue lengths at inbound gates

- Dock availability

- Progress of loading and unloading

Routing engines that “see” this information can throttle arrivals, re-order stops, or route vehicles toward less congested hubs. Instead of drivers waiting in long yard queues, the network self-balances based on real capacity.

5. Order and customer context

The smartest routing decisions are business-aware. IoT data gains real power when combined with information such as:

- Customer priority and service agreements

- Promised delivery windows

- Shipment value and handling requirements

A dynamic routing engine can then decide, for example, to re-allocate capacity to a high-priority order, even if it slightly extends another route—because it understands the revenue and relationship impact, not just the distance.

How IoT data feeds smarter routing decisions

Connecting devices is only the start. The real value lies in how IoT data flows into decision-making.

Data ingestion and stream processing

Vehicle, sensor, and external feeds send data to a central platform over cellular, satellite, or Wi‑Fi networks. Modern supply chain systems rely on streaming data pipelines that can:

- Ingest thousands of events per second

- Normalize different formats

- Filter out noise and duplicates

Latency matters. A traffic incident alert received 20 minutes late is almost useless for routing. Leading logistics providers emphasize near real-time data processing as a prerequisite for operational use of IoT data.

Analytics, prediction, and optimization

On top of these streams, analytics models estimate:

- Remaining driving time and ETAs

- Probability of late deliveries or missed time windows

- Vehicle health and likelihood of breakdown

Optimization engines—drawing on operations research and data-driven models—then use these predictions, along with constraints such as capacity, time windows, and driver regulations, to compute or update routes. When new data arrives, the engine can re-evaluate, but with guardrails to avoid overwhelming drivers with constant changes.

Execution and continuous feedback

Updated routes and ETAs are pushed to driver apps, in-cab devices, and control tower dashboards. As drivers follow (or occasionally deviate from) instructions, their behavior generates more IoT data. This creates a feedback loop that continuously improves the accuracy of ETAs, optimization rules, and operational playbooks.

Real-world impact: What smarter routing looks like in practice

The impact of IoT-driven routing is visible at global scale. UPS is a widely cited example: its ORION (On‑Road Integrated Optimization and Navigation) platform uses telematics, customer data, and advanced optimization techniques to design highly efficient delivery routes. Public case studies indicate ORION has helped cut roughly 100 million miles per year, saving hundreds of millions of dollars and significantly reducing CO₂ emissions.

Other logistics providers report double-digit reductions in fuel consumption, 20–30% improvements in on-time delivery, and better use of trailers and linehaul capacity after integrating IoT sensors with real-time routing tools.

Beyond hard savings, smarter routing transforms the customer experience. Live ETAs, proactive delay notifications, and more reliable time windows reduce “Where is my order?” calls and make value-added services like same-day or time-definite delivery economically viable.

Building the technology foundation for IoT-enabled routing

To harness IoT data streams effectively, supply chain organizations need the right technology stack.

Connected assets and telematics hardware

The journey begins with equipping vehicles, trailers, and sometimes returnable containers with sensors and connectivity. Common approaches include:

- OEM-installed telematics units

- Aftermarket devices in mixed fleets

- Low-power trackers and smart labels on pallets or containers

Key questions to address early: battery life, coverage across operating regions, remote configuration capabilities, and installation/maintenance processes.

Secure connectivity and scalable platforms

Data has to travel securely and reliably from the edge to the cloud. Most fleets rely on cellular networks, sometimes backed up by satellite links in remote areas, and Wi‑Fi in yards or hubs. On the back end, cloud platforms handle ingestion, processing, and storage, scaling elastically for peak seasons.

Many enterprises blend off‑the‑shelf routing or TMS platforms with custom application development services to adapt dashboards, exception workflows, and mobile experiences to their specific operating models and user roles.

Integration with TMS, WMS, and ERP

Routing decisions sit at the intersection of planning and execution. They depend on order data from ERP, constraints from the transport management system (TMS), and information from warehouse management (WMS) about dock schedules and cut-off times.

API-based integration and event-driven architectures help ensure that:

- Every routing decision reflects the latest orders and constraints.

- Changes are visible across planning, execution, and customer-service teams.

- KPIs and financial impacts are tracked consistently.

Data governance, security, and privacy

With hundreds or thousands of devices in the field, data governance becomes essential. Organizations must define:

- Who can access which data streams

- How long different data types are retained

- How sensitive information, such as driver behavior data, is protected

Strong encryption, authentication, and vulnerability management are now mandatory to protect location traces, customer information, and network operations from cyber threats.

People and process: The human side of smarter routing

Technology alone does not guarantee better routing decisions. Organizations must evolve their processes and culture to fully benefit.

Drivers may initially perceive dynamic routing tools as a challenge to their expertise, while planners may worry that algorithms replace their judgment. Successful programs treat IoT and analytics as decision support, not as a black box that overrules human insight.

Engaging drivers early, sharing performance improvements, and incorporating their feedback into routing rules builds trust. Likewise, giving planners transparency into how optimization engines make decisions encourages them to use data as a partner rather than a rival.

IoT-driven routing also supports a shift from reactive firefighting to proactive management. Control-tower teams can see issues before they escalate—such as heavy congestion around a hub or a storm approaching a critical lane—and act ahead of time using defined playbooks.

Common challenges and how to overcome them

Despite clear benefits, IoT-based routing introduces its own challenges:

- Data quality: Incomplete locations, misconfigured sensors, or inconsistent timestamps can undermine routing logic. Device management, validation rules, and continuous monitoring are essential.

- Interoperability: Mixed vendors and legacy systems make it harder to standardize data. Common data models and middleware help bridge the gaps.

- Connectivity gaps: Rural and cross-border routes may have patchy coverage. Store‑and‑forward mechanisms and edge processing can reduce blind spots.

- Change management: Moving from fixed to dynamic routing affects drivers, planners, and customer expectations. Phased rollouts and well-defined pilots tend to work better than “big bang” deployments.

- Cost justification: Hardware, connectivity, and platforms require investment. Tying projects to clear KPIs—fuel savings, reduced miles, better asset utilization, and improved customer retention—strengthens the business case.

A practical roadmap to get started

For organizations at the beginning of their IoT journey, a pragmatic roadmap might look like this:

- Define the routing problem clearly. For example: “reduce last-mile miles per stop by 8%” or “improve on-time performance in a given city by 10%.”

- Assess current data and gaps. Identify what telematics, order, and facility data you already have—and where IoT sensors would deliver the highest value.

- Run a focused pilot. Choose one region, lane, or fleet segment to test IoT-enabled routing with manageable complexity.

- Set baseline KPIs. Track miles per stop, fuel consumption, on-time rate, dwell time, and complaints both before and after the pilot.

- Iterate and refine. Use pilot results to adjust routing rules, data models, and processes, then expand to additional regions or fleets.

- Operationalize the change. Embed new practices into SOPs, training, incentives, and reporting so that smarter routing becomes part of daily operations, not a one-off project.

Conclusion

Modern supply chains are simply too complex and too fast-moving for static routing. IoT data streams—from vehicles, assets, infrastructure, and facilities—offer a real-time view of what is happening on the ground. When combined with robust analytics, optimization engines, and thoughtful change management, this data enables logistics teams to design routes that are safer, greener, and more profitable.

The organizations that stand out will be those that treat IoT as the nervous system of their supply chain—constantly sensing, learning, and helping people make better routing decisions every hour of the day.

FAQs

1. What is IoT-based routing in supply chains?

IoT-based routing uses data from connected devices—such as vehicle telematics, asset trackers, and dock sensors—to continuously update and optimize delivery routes. Instead of relying on static, pre-planned routes, decision engines adapt to real-time changes in traffic, weather, orders, and facility conditions.

2. How does IoT improve route optimization and delivery performance?

IoT streams provide accurate, real-time inputs for routing algorithms. This allows companies to reduce empty miles, avoid congestion, and respond quickly to disruptions. The result is better on-time performance, lower fuel and maintenance costs, and more reliable ETAs for customers.

3. Which sensors are most useful for smarter routing?

The most commonly used devices include GPS trackers and telematics units in vehicles, temperature and humidity sensors for cold-chain shipments, door and motion sensors for security, and yard or dock sensors that track queues and loading progress. Combined with traffic and weather feeds, these sensors create a rich picture of the network.

4. Is IoT-based routing only suitable for large enterprises?

No. Large global carriers were early adopters, but cloud-based telematics and routing platforms have lowered the barrier to entry. Mid-sized and smaller logistics providers can start with a subset of their fleet or a specific region, then scale as they demonstrate value and refine their processes.

5. How can companies measure ROI for IoT-enabled routing?

Typical metrics include total miles driven, fuel usage per stop, on-time delivery rate, average dwell time, and the number of stops per route. Comparing these KPIs before and after IoT-based routing—ideally through controlled pilots—provides a clear view of financial and service-level impact.

6. What should organizations look for in a technology partner for IoT routing?

Companies should seek partners that can integrate telematics, IoT sensor data, and order information into a unified platform; provide strong optimization and analytics capabilities; and support secure, scalable operations. Proven implementation experience, transparent reporting, and a clear product roadmap are also critical for long-term success.

Leave a Reply