In the cargo and logistics industry, where the movement of massive loads is routine, accurate weight measurement is critical. Whether it’s for safety compliance, billing, or load optimization, knowing the exact weight of cargo during lifting operations can make a significant difference. This is where Crane Weight Scales come into play.

Crane weight scales are precision instruments designed to measure the weight of heavy loads lifted by cranes in real-time. These scales are commonly used in ports, shipping yards, construction sites, and industrial warehouses. In this blog, we’ll explore why crane weight scales have become indispensable tools in cargo sites, how they work, and the many benefits they offer in modern logistics and heavy lifting operations.

What Are Crane Weight Scales?

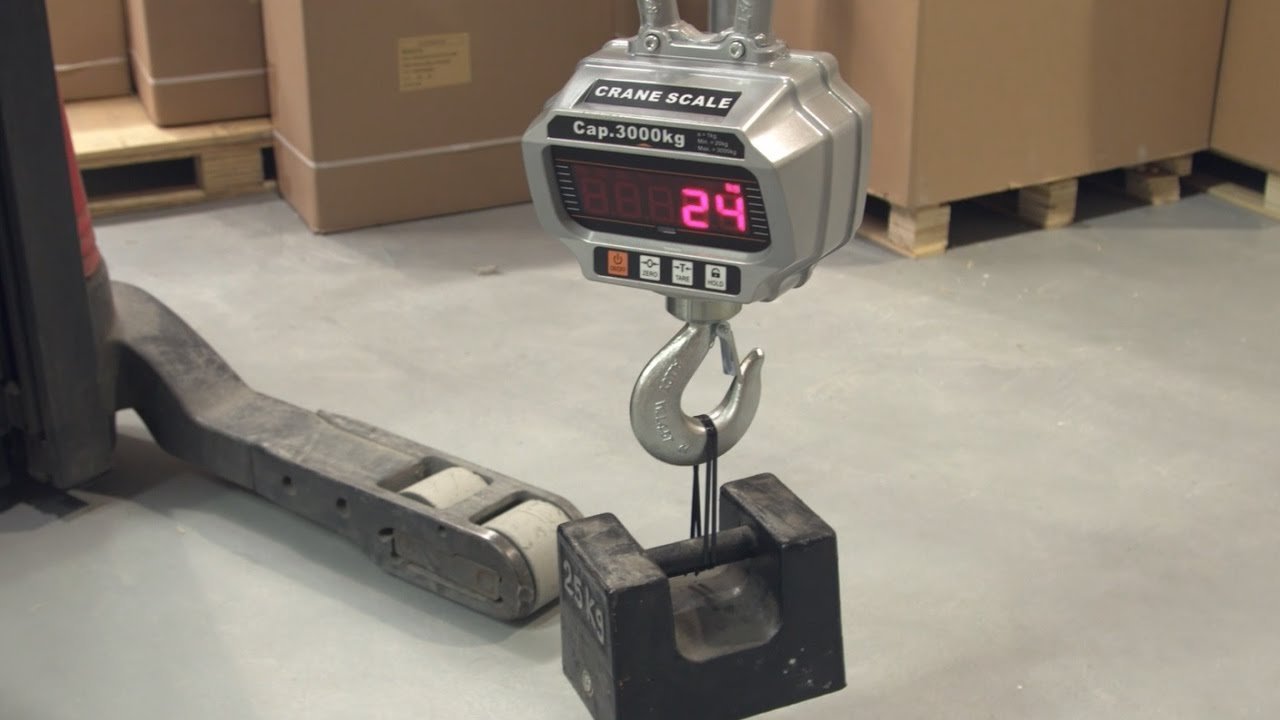

Crane weight scales, also known as crane scales or load cell systems, are weighing devices integrated with cranes to provide real-time load measurement during lifting. These systems typically include:

- A load cell or dynamometer attached to the crane hook or lifting mechanism

- A digital display or remote monitor

- Wireless communication for remote monitoring

- Optional data logging and software integration features

These systems ensure that the operator knows exactly how much weight is being lifted, which helps maintain safety, operational efficiency, and compliance with load regulations.

1. Enhancing Load Safety and Compliance

One of the most critical reasons cargo sites depend on Crane Weight Scales is safety. Overloading a crane can result in catastrophic accidents, equipment damage, or even loss of life. Regulations from OSHA and other authorities strictly limit the weight that cranes can safely handle.

Crane weight scales ensure that the load remains within safe limits. When the operator knows the exact weight before and during a lift, they can take preventive action if the load exceeds capacity. This real-time awareness helps:

- Prevent crane tip-overs and structural failure

- Maintain stability during lifting and transport

- Ensure compliance with industry weight regulations

2. Streamlining Cargo Handling and Inventory

In ports and shipping terminals, where hundreds or thousands of containers are moved daily, crane weight scales allow for fast and accurate cargo handling. Instead of weighing loads separately using floor scales, operators can lift and weigh simultaneously—saving time and labor.

Additionally, many modern crane weight scales can interface with inventory management software. This integration allows:

- Automatic weight logging per lift

- Real-time inventory updates

- Data synchronization for shipment records

This capability significantly streamlines warehouse and cargo yard operations and enhances inventory accuracy.

3. Improving Billing Accuracy and Transparency

In cargo logistics, especially when transporting bulk goods or freight charged by weight, accurate billing is essential. Errors in weight estimation can lead to disputes with clients or revenue loss.

Crane weight scales provide certified and traceable weight measurements that ensure fair and accurate billing. This transparency builds trust with clients and helps logistics firms maintain better financial control. Key benefits include:

- Elimination of guesswork and manual logging

- Compliance with legal-for-trade requirements

- Clear audit trails for every shipment

4. Boosting Operational Efficiency

Time is money in the cargo business. Traditional methods of weighing—such as floor scales or weighbridges—often require additional handling, movement of goods, or waiting times. This not only slows operations but also increases labor costs.

With Crane Weight Scales, lifting and weighing are performed in a single motion. This streamlined process:

- Reduces loading and unloading times

- Minimizes double handling of cargo

- Speeds up the workflow in busy ports and yards

The result is faster turnaround times, reduced bottlenecks, and improved operational efficiency.

5. Versatile Applications in Diverse Cargo Environments

Crane weight scales are designed for versatility. They can be used with different types of cranes—overhead cranes, gantry cranes, tower cranes, mobile cranes, and more. Whether you’re dealing with containerized freight, raw materials, heavy equipment, or loose bulk, crane scales adapt to various load shapes and sizes.

Common cargo environments that benefit from crane scales include:

- Seaports and inland terminals

- Steel and metal processing plants

- Construction material yards

- Mining and aggregate operations

- Oil and gas transport hubs

This broad applicability makes them a smart investment across industries.

6. Durability and Reliability in Harsh Conditions

Cargo sites often face challenging environments, such as extreme temperatures, dust, moisture, and rough handling. Crane weight scales are engineered to withstand these conditions. Most models are built with:

- Rugged stainless steel or aluminum enclosures

- IP-rated protection against dust and water

- Shock and vibration resistance

- Long battery life and wireless functionality

This robustness ensures reliable operation and minimal downtime, even in the toughest environments.

7. Data Logging and Remote Monitoring Capabilities

Modern crane weight scales aren’t just about real-time readings—they also offer advanced features like:

- Data logging: Automatically record each lift’s weight, time, and ID for record-keeping and analysis.

- Wireless transmission: View real-time data on handheld devices or control room monitors.

- Integration with ERP/WMS: Seamless flow of weight data into enterprise systems for full visibility and traceability.

These digital features support smarter decision-making, auditing, and compliance tracking—particularly in large-scale operations.

8. Cost Savings in the Long Run

While Crane Weight Scales require an upfront investment, they offer significant cost savings over time by:

- Reducing labor costs associated with manual weighing

- Preventing equipment damage due to overloading

- Lowering insurance premiums through enhanced safety

- Avoiding costly downtime and penalties from regulatory violations

With improved accuracy, safety, and efficiency, companies quickly realize ROI through streamlined operations and reduced risks.

Conclusion: A Smart Tool for Cargo Success

In fast-paced, high-stakes cargo environments, Crane Weight Scales have proven to be more than just measuring tools. They are essential instruments that enhance safety, efficiency, accountability, and profitability. By providing real-time weight data during lifts, these scales help cargo site managers make informed decisions, avoid overloads, and optimize workflows.

Whether you manage a busy seaport, warehouse, or logistics hub, investing in crane weight scales is a strategic move that ensures compliance, maximizes throughput, and safeguards your most valuable assets—your people, your equipment, and your cargo.

If you’re looking to upgrade your weighing system, consider high-performance crane weight scales that deliver precision, durability, and smart integration. In the world of heavy lifting, knowledge is power—and accurate weight measurement is the key.

Leave a Reply