The manufacturing and industrial realm is quite diverse, with numerous machines, humans, and processes working together to produce the best goods. In this labyrinth of tools and processes, gripping and clamping stand as two of the most important solutions that have unique significance in the manufacturing industry. Gripping and clamping solutions ensure precision and efficiency in the manufacturing processes. They ensure that the components are held securely in the machines during machining and other operations.

The gripping and clamping solutions are being revolutionised by e-technology. Read below to know the future of these solutions. However, before delving into that, this blog will introduce you to what these solutions are and their various types.

Understanding Gripping and Clamping Solutions

Gripping and clamping mechanisms are an integral part of manufacturing processes. These solutions provide the means to securely hold workpieces in position during assembly, machining, and inspection processes. The different types of clamping device and gripping systems ensure the correct alignment of components in an automotive assembly line. They are also used while holding delicate materials to place them during 3D printing. Their role is crucial in varying industries.

In earlier times, the gripping and clamping methods significantly relied on manual labour. Traditionally, these mechanisms were based on conventional mechanical systems. The effectiveness of these methods for clamping and gripping cannot be neglected or degraded. However, there were several limitations when the conventional methods were used. These limitations were witnessed in efficiency, adaptability and precision. Also, the traditional types of clamping system and grippers needed extensive human intervention. This led to potential safety hazards and increased manual labour. It also resulted in increased costs and irregularities.

The limitations of the traditional vacuum clamping system and other conventional clamping and gripping systems demanded advancements. Considering these demands, e-technology has entered the manufacturing world. It is constantly revolutionising the clamping and gripping methods. The advent of e-technology is changing the manufacturing processes across varying industries.

Types of Clamping Device and Systems

The modern manufacturing industry uses a wide range of clamping devices. All these systems and devices have different applications. Some of the most significant types of clamping system include-

Vacuum Clamping System

Hydraulic Clamping System

Pneumatic Clamping System

Magnetic Clamping System

Mechanical Clamping System

Types of Gripping Device and Systems

Grippers are another essential component in manufacturing automation. They allow the robots to grasp and manipulate objects effectively. Below are the various types of grippers used in the manufacturing industry.

- Magnetic Grippers

- Parallel Jaw Grippers

- Angular Grippers

- Vacuum Grippers

- Finger or Compliant Grippers

- Rotary Grippers

- Adaptive Grippers

E-Technology’s Transformative Impact on Gripping and Clamping Solutions

E-technology has ushered in a transformative era for clamping and gripping solutions in production, revolutionising traditional methods. It is significantly introducing modern capabilities which improve adaptability, efficiency, and precision. By combining electrical sensors, actuators, and smart control systems into clamping and gripping devices, e-technology has allowed companies to overcome long-standing challenges and unlock new levels of effectiveness across a broad range of uses.

One of the more significant impacts of e-technology on clamping and gripping lies in its ability to improve flexibility and automation. Smart gripping and clamping solutions built with sensors are able to collect real-time information about workpiece dimensions, surface characteristics, and environmental problems. This particular data makes it possible to make dynamic adjustments in clamping and gripping force, ensuring ideal performance and minimising damage or errors during operations.

Additionally, e-technology has facilitated the improvement of reconfigurable and modular gripping and clamping systems. Manufacturers can now quickly interchange components or even adjust configurations through electronic commands, streamlining and optimising production and changeover processes throughput. This particular adaptability is especially important in industries in which quick adaptation to changing market demands is important for competitiveness.

Moreover, the integration of e-technology enables remote control and monitoring features in clamping and gripping devices. Manufacturers are able to oversee operations from anywhere on the planet, enhancing responsiveness and flexibility in production processes. Predictive maintenance capabilities likewise enable proactive interventions to stop equipment failures and downtime, maximising productivity and uptime.

To conclude, technology’s transformative effect on clamping and gripping solutions is driving efficiency and innovation in production, paving the way for a powerful future wherein precision, flexibility, and automation are paramount. Embrace the possibility of e-technology makes it possible for industries to remain competitive and flourish in an increasingly electronic and interconnected world.

Applications Across Industries

E-technology’s transformative effect on clamping and gripping solutions transcends industry boundaries, with applications spanning across a diverse range of sectors. For auto manufacturing, robotic gripping systems built with advanced sensors and AI algorithms ensure accurate handling of complicated elements, like engine parts and body panels, enhancing assembly efficiency and product quality. Aerospace assembly advantages from e-technology-driven clamping programs guarantee the positioning and fixation of vital aircraft structures with unparalleled precision, contributing to reliability and safety in aviation.

In the consumer electronics industry, the integration of delicate robotic grippers with e-technology capabilities enables fine handling of vulnerable elements, decreasing the danger of harm and improving production yield rates. Furthermore, the adoption of e-technology in gripping and clamping is reshaping the landscape of additive manufacturing (3D printing), in which automated grippers and clamps ensure constant build quality, minimising warping or distortion, and improving basic dependability of the printing operation.

Additionally, industries, for example, drugs, beverages, and food, as well as consumer products, benefit from e-technology-driven clamping and gripping solutions that improve safety, quality, and efficiency in manufacturing processes. From pick-and-place operations to palletizing and packaging, the versatility and adaptability of e-technology-enabled clamping and gripping systems enable companies to satisfy the changing demands of their respective markets while keeping a competitive advantage in a progressively automated world.

Takeaway

In conclusion, technology’s transformative role in gripping and clamping solutions is reshaping the landscape of manufacturing, ushering in a dynamic future characterised by enhanced precision, efficiency, and flexibility. From smart sensors and AI-driven algorithms to remote monitoring and modular designs, the advancements enabled by e-technology are revolutionising manufacturing processes across industries. As industries continue to embrace digital transformation, leveraging the potential of e-technology in gripping and clamping solutions will be essential for staying competitive and driving innovation in the ever-evolving manufacturing landscape.

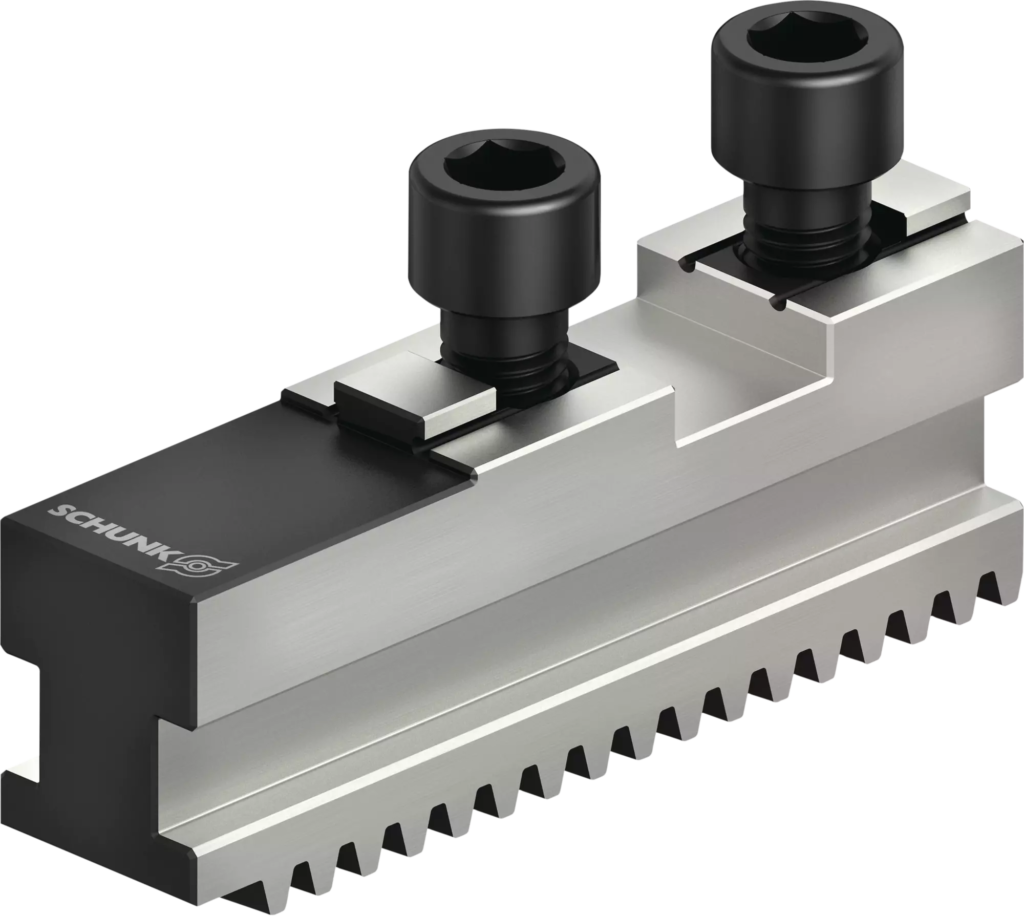

Schunk stands out as a leader in offering the most effective grippers and clamping devices because of our commitment to innovation, quality, and dependability. With years of expertise in the field, Schunk provides an extensive selection of grippers and clamping solutions customised to varied manufacturing applications. Our products are characterised by precision engineering, strong construction, as well as innovative features like integrated intelligent control systems and sensors.

Frequently Asked Questions

What are gripping and clamping solutions?

The clamping and gripping mechanisms are an essential part of the manufacturing processes. These solutions help to securely hold the workpiece in position during machining, inspection and assembly in the manufacturing processes.

How e-technology is transforming gripping and clamping methods?

E-technology is integrating these solutions with advanced technologies to make them more independent and efficient.

Leave a Reply