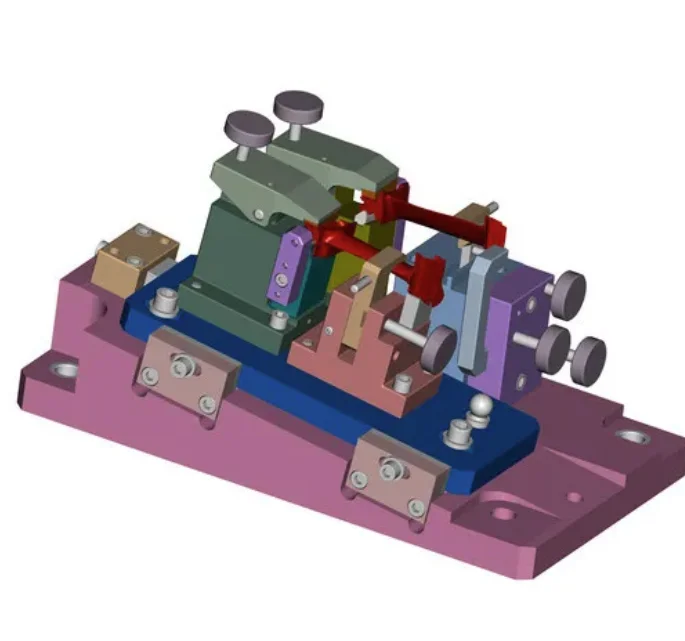

CNC manufacturing relies on accuracy, repeatability, and controlled processes to deliver parts that meet strict tolerance requirements. Even the most advanced CNC machines cannot perform at their best without proper workholding solutions. This is why jig and fixture design remains a critical element in precision machining environments. A well-engineered system ensures stable positioning, minimizes vibration, and allows machines to operate consistently across long production cycles.

As industries demand faster turnaround times and tighter quality standards, manufacturers must eliminate variability wherever possible. Custom-built jigs and fixtures tooling provides controlled locating and clamping, allowing CNC shops to maintain dimensional accuracy while improving productivity and reducing waste.

Importance of Jigs and Fixtures in CNC Operations

Foundation of Machining Accuracy

Jigs and fixtures act as the physical foundation of CNC machining. They define how a workpiece is positioned relative to the cutting tool and machine axes. Without reliable locating, even small deviations can result in tolerance failures. Proper jigs and fixtures locating establishes repeatable reference points that ensure each machining operation starts from the same position, regardless of operator or machine.

Contribution to Process Consistency

Consistency is essential in batch and mass production. A well-designed fixture reduces setup variation and ensures uniform part quality. Operators can load components quickly, knowing that the fixture automatically aligns the part correctly. This consistency shortens cycle times and reduces inspection and rework requirements.

Core Principles of Jig and Fixture Engineering

Locating Techniques for Stable Positioning

Effective locating restricts unnecessary movement while allowing easy loading and unloading. Principles such as three-point base support and controlled side location prevent over-constraining the part. Accurate locating improves dimensional stability and supports repeatable machining across multiple cycles and machines.

Clamping Methods That Protect Part Integrity

Clamping must secure the workpiece without distortion. Excessive force can deform thin sections, while insufficient force can cause chatter. Balanced clamping distributes pressure evenly and maintains rigidity during cutting. Skilled jig and fixture design devices consider cutting forces, material properties, and tool access when selecting clamping strategies.

Materials and Build Quality in CNC Tooling

Selecting Materials for Performance and Durability

Fixture materials affect strength, weight, and lifespan. Hardened steel is ideal for high-volume production due to wear resistance. Aluminum fixtures are lighter and easier to handle, making them suitable for medium-volume runs. In some cases, softer materials are used at contact points to protect finished surfaces.

Structural Design for Rigidity

Rigidity is critical for maintaining accuracy. Fixtures must resist cutting forces without flexing or shifting. Designers often use reinforced bases, ribs, and support elements to enhance stiffness. Proper structural planning also improves chip evacuation and coolant flow, contributing to cleaner machining conditions.

Custom Jig and Fixture Solutions for Complex CNC Parts

Adapting to Unique Component Shapes

Complex geometries often require custom solutions. Standard fixtures may fail to support irregular shapes or multi-axis machining requirements. Custom jigs and fixtures tooling matches the fixture to the part geometry, ensuring secure contact points and stable support throughout the machining process.

Flexibility for Changing Production Needs

Modern manufacturing environments demand adaptability. Custom fixtures can be designed with modular features that allow adjustments for design updates or part families. This flexibility reduces downtime and avoids the cost of complete fixture replacement when production requirements change.

Common Types of Jigs and Fixtures in CNC Machining

Fixtures for Different Machining Processes

Each CNC process requires specific workholding approaches. Drilling jigs guide tools accurately for hole placement. Milling fixtures support complex surface machining and multi-axis operations. Turning fixtures ensure concentricity and balance during rotational machining. Each design focuses on stability and accessibility for its specific application.

Modular and Dedicated Systems

Manufacturers often choose between modular and dedicated fixtures based on production volume. Well-planned systems offer advantages such as:

- Faster setup and changeover times

- Improved repeatability across machines

- Reduced long-term tooling costs

Quality Control Benefits of Proper Workholding

Reduction of Human Error

Fixtures that guide part placement reduce reliance on operator judgment. Clear locating points and intuitive loading features help prevent incorrect setups. This consistency improves quality and reduces scrap rates, especially in high-volume CNC production.

Support for Inspection and Measurement

Accurate workholding simplifies in-process inspection. When parts are consistently located, measurement results become more reliable. This improves confidence in quality data and reduces the need for repeated checks or adjustments.

Safety and Efficiency in CNC Environments

Enhancing Operator Safety

Secure jigs and fixtures minimize the risk of part movement during machining. Stable workholding protects operators from unexpected part ejection or tool damage. A safer setup also reduces machine downtime caused by crashes or fixture failure.

Improving Overall Shop Efficiency

Efficient workholding reduces setup time and allows machines to run closer to their optimal parameters. Less vibration and movement lead to smoother cuts and longer tool life. Over time, these improvements translate into higher throughput and lower operating costs.

Digital Tools in Modern Fixture Design

CAD Modeling and Simulation

Computer-aided design plays a major role in modern fixture development. Designers can simulate loads, clearances, and clamping forces before manufacturing begins. This approach reduces trial-and-error and ensures that the fixture performs as expected in real production conditions.

Automation-Ready Fixture Systems

As CNC automation increases, fixtures are evolving to support robotic loading and monitoring. Sensors can verify part presence and clamping status, improving process reliability. Automation-ready jig and fixture design devices support unattended machining and higher production efficiency.

Choosing the Right Jig and Fixture Design Partner

Importance of Engineering Expertise

An experienced design partner understands machining processes, materials, and tolerance requirements. Their expertise ensures that each fixture aligns with production goals and quality standards. Strong engineering input leads to reliable solutions that perform consistently under real shop conditions.

Long-Term Value of Precision Tooling

Investing in high-quality jigs and fixtures delivers long-term benefits. Reduced scrap, faster cycles, and extended tool life improve overall profitability. When designed with scalability in mind, these solutions continue to support evolving production needs. In CNC manufacturing, precision begins before the first cut. Reliable jig and fixture design provides the stability, accuracy, and repeatability required for modern machining. By focusing on proper locating, balanced clamping, and durable construction, manufacturers can achieve consistent results while meeting the growing demands of precision engineering.

Leave a Reply