Introduction

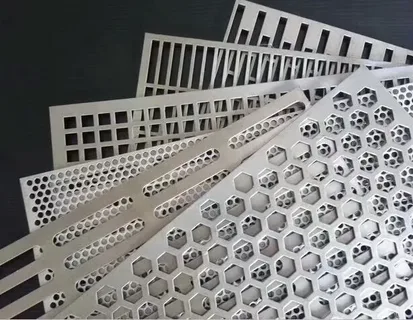

Perforated metal sheets are used in various industries, including construction, automotive, architecture, and manufacturing. These sheets have small holes punched through them, making them useful for ventilation, filtration, soundproofing, and even decorative purposes. But have you ever wondered what materials are used to manufacture perforated metal sheets? The choice of material is crucial as it determines the sheet’s strength, durability, resistance to corrosion, and overall performance.

In this article, we will explore the most common materials used to manufacture perforated metal sheets. We will discuss their properties, benefits, and best applications so that you can understand which material suits your needs best.

Note :Looking for high-quality Perforated Metal Sheets for your next project? Whether you need durable stainless steel, lightweight aluminum, or decorative brass sheets, we have the perfect solution for you! Contact us today to explore our wide range of materials and get expert advice on selecting the best perforated metal sheet for your needs.

1. Stainless Steel

What is Stainless Steel?

Stainless steel is a metal alloy made primarily from iron, chromium, and other elements like nickel and carbon. It is well-known for its resistance to rust and corrosion.

Why is Stainless Steel Used in Perforated Metal Sheets?

Stainless steel is one of the most popular choices for perforated metal sheets because:

- It resists corrosion, making it ideal for outdoor use.

- It has high strength and durability.

- It maintains its appearance over time.

- It requires minimal maintenance.

Where is Stainless Steel Perforated Metal Used?

- Architectural designs for buildings and facades

- Food and beverage industry (as it is safe and hygienic)

- Chemical and pharmaceutical industries

- Outdoor structures like fences and railings

2. Aluminum

What is Aluminum?

Aluminum is a lightweight, non-magnetic metal known for its resistance to corrosion and ability to conduct heat and electricity.

Why is Aluminum Used in Perforated Metal Sheets?

- It is lightweight, making it easy to handle and install.

- It resists rust and corrosion, even in humid or coastal areas.

- It is highly recyclable and eco-friendly.

- It provides an excellent balance between strength and flexibility.

Where is Aluminum Perforated Metal Used?

- Airplane and automotive industries (because of its lightweight nature)

- Decorative wall panels and ceilings

- Noise reduction barriers on highways

- Ventilation grilles and HVAC systems

3. Carbon Steel

What is Carbon Steel?

Carbon steel is a type of steel that contains carbon as the main alloying element. It is strong and cost-effective but can be prone to rust if not treated properly.

Why is Carbon Steel Used in Perforated Metal Sheets?

- It is stronger than many other materials.

- It is more affordable compared to stainless steel.

- It is easy to work with and can be welded, shaped, or cut easily.

- It can be coated or painted to improve corrosion resistance.

Where is Carbon Steel Perforated Metal Used?

- Industrial machinery and manufacturing

- Security fencing and barriers

- Heavy-duty shelving and storage racks

- Agricultural equipment

4. Galvanized Steel

What is Galvanized Steel?

Galvanized steel is regular steel coated with a layer of zinc to protect it from rust and corrosion.

Why is Galvanized Steel Used in Perforated Metal Sheets?

- It is highly resistant to rust and corrosion.

- It is stronger than aluminum but more affordable than stainless steel.

- It has a long lifespan, especially in outdoor environments.

- It requires little maintenance.

Where is Galvanized Steel Perforated Metal Used?

- Outdoor fencing and gates

- Roofing and drainage systems

- Industrial safety barriers

- Automotive components

5. Copper

What is Copper?

Copper is a reddish-brown metal known for its excellent electrical and thermal conductivity, corrosion resistance, and antimicrobial properties.

Why is Copper Used in Perforated Metal Sheets?

- It has natural antimicrobial properties, making it ideal for medical applications.

- It resists corrosion, especially in marine environments.

- It has a unique and attractive appearance.

- It is highly conductive, making it useful in electrical applications.

Where is Copper Perforated Metal Used?

- Decorative elements in buildings and furniture

- Electrical and electronic components

- HVAC systems and heat exchangers

- Water filtration systems

6. Brass

What is Brass?

Brass is an alloy of copper and zinc, known for its gold-like appearance, strength, and corrosion resistance.

Why is Brass Used in Perforated Metal Sheets?

- It is highly durable and resistant to wear.

- It has a decorative appeal with a shiny, golden look.

- It is easy to shape and machine.

- It resists tarnishing and corrosion.

Where is Brass Perforated Metal Used?

- Decorative screens and grilles

- Musical instruments

- Plumbing fixtures

- Art and craft applications

7. Titanium

What is Titanium?

Titanium is a strong, lightweight metal with exceptional corrosion resistance and high strength-to-weight ratio.

Why is Titanium Used in Perforated Metal Sheets?

- It is extremely strong but lightweight.

- It resists corrosion even in harsh environments like seawater.

- It is biocompatible, meaning it can be used in medical implants.

- It withstands extreme temperatures.

Where is Titanium Perforated Metal Used?

- Aerospace and aviation industries

- Medical implants and devices

- Chemical processing plants

- High-performance sports equipment

How to Choose the Right Material for Your Perforated Metal Sheet?

When selecting the right material for a perforated metal sheet, consider the following factors:

- Environment: If exposed to moisture, stainless steel or galvanized steel may be better than carbon steel.

- Strength Requirements: If you need a strong but lightweight material, aluminum or titanium is a good choice.

- Aesthetics: For decorative applications, brass or copper can add a stylish touch.

- Budget: Carbon steel and galvanized steel are more affordable, while titanium and stainless steel are premium options.

- Application: If the sheet is for industrial or heavy-duty use, carbon steel or stainless steel is best.

Conclusion

Perforated metal sheets come in various materials, each offering unique benefits. Whether you need strength, corrosion resistance, or aesthetics, there is a material that suits your application. Stainless steel and aluminum are popular for their durability, while copper and brass are chosen for their looks. Carbon steel and galvanized steel offer cost-effective options for industrial use. For high-performance needs, titanium is an exceptional choice.

Understanding the different materials helps you make the best decision for your project. No matter what you choose, perforated metal sheets remain a versatile and essential material in many industries.

For more insightful articles related to this topic, feel free to visit : techners.net

Leave a Reply