Conveyor belts are the backbone of numerous industries, ensuring the seamless movement of materials across production lines. However, wear and tear are inevitable, making reliable repair and maintenance solutions critical to minimizing downtime and maximizing efficiency. Oliver Rubber Industries LLP, a Jodhpur, Rajasthan-based company with over 35 years of expertise, has established itself as a trusted leader in this domain. Specializing in cold and hot vulcanizing kits, rubber sheets, pulley lagging materials, and innovative repair solutions, Oliver Rubber is committed to extending the lifespan and performance of conveyor systems worldwide. Among the standout products in the market, Rema Tip Top SC 4000 Glue is a benchmark for quality adhesives, and Oliver Rubber offers a compelling alternative that rivals its capabilities.

Oliver Rubber Industries: A Legacy of Excellence

Founded over three decades ago, Oliver Rubber Industries LLP has grown into a powerhouse in the conveyor belt maintenance sector. Based in the industrial hub of Jodhpur, the company combines traditional craftsmanship with modern innovation to deliver products that meet the rigorous demands of industries such as mining, manufacturing, and logistics. Their extensive product range addresses every aspect of conveyor belt care, from routine splicing to emergency repairs, ensuring that businesses can rely on durable, efficient solutions tailored to their needs.

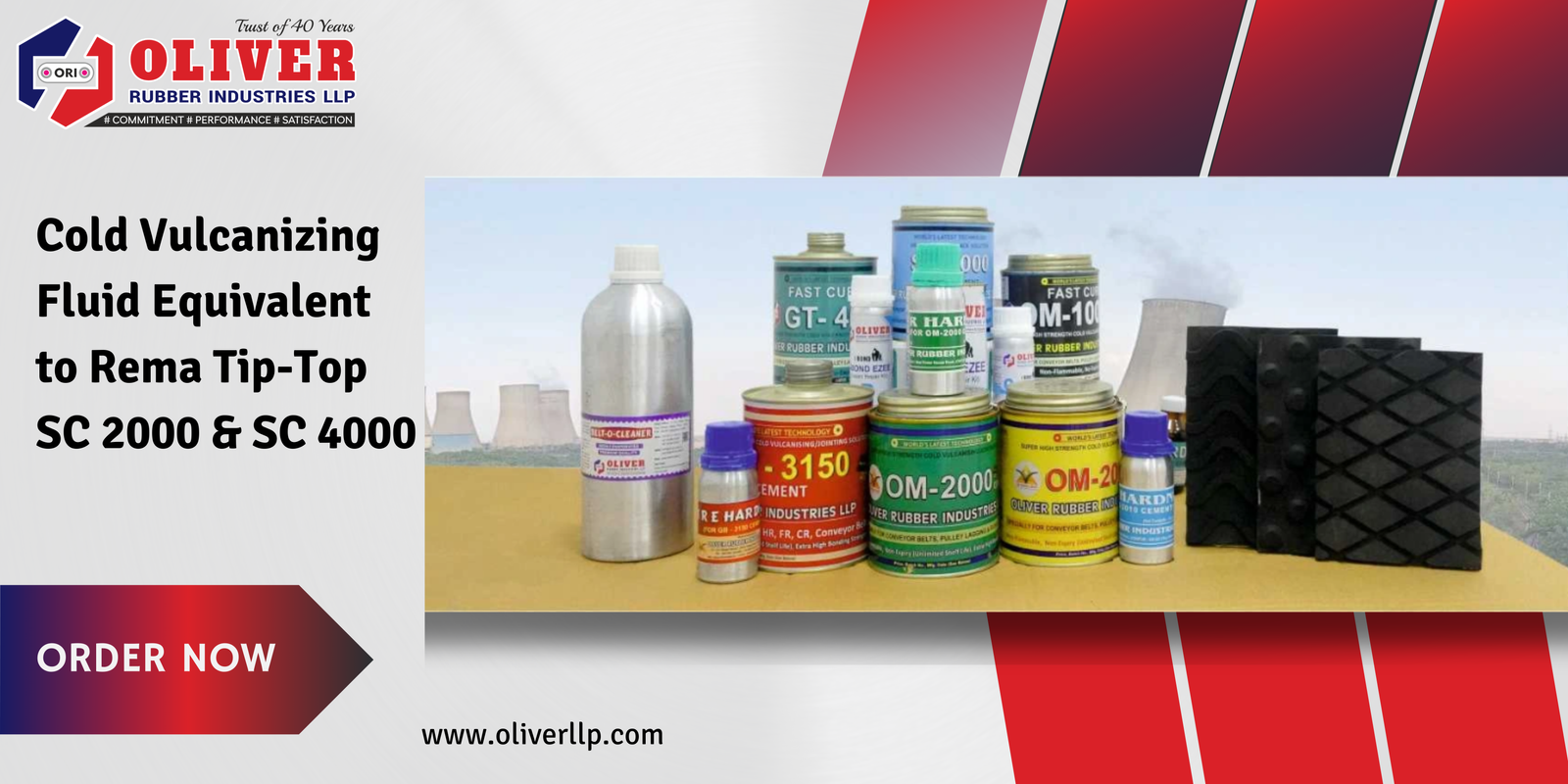

A Diverse Product Portfolio

Oliver Rubber’s offerings are designed to tackle a wide array of conveyor belt challenges. Let’s explore their key products and how they align with industry standards, including those set by adhesives like Rema Tip Top SC 4000 Glue.

- Cold Vulcanizing Solutions

The flagship OM-2000 adhesive is a double-ingredient, multipurpose solution that excels in splicing and repairing conveyor belts without requiring heat. This cold vulcanizing method is a game-changer for operations seeking convenience and speed. OM-2000 bonds rubber to metal, fabric, and other substrates with exceptional strength, making it a versatile alternative to hot vulcanizing. Its ease of use and reliability make it a go-to choice for many professionals. - Hot Vulcanizing Kits

For more extensive damage, such as large tears or holes, Oliver Rubber’s hot vulcanizing kits deliver robust repairs. These kits utilize specialized presses to create permanent bonds, restoring the belt’s structural integrity. This solution is ideal for heavy-duty applications where durability is non-negotiable. - Rubber Sheets

Oliver Rubber manufactures an array of rubber sheets, including chloroprene, natural, EPDM, and silicone variants. These sheets are engineered for specific industrial needs, offering resistance to abrasion, weathering, and chemicals. They serve as essential components in conveyor system maintenance and repair. - Pulley Lagging Materials

Products like Button Top and Wavy Top Pulley Lagging enhance the performance of conveyor pulleys by improving grip, reducing slippage, and extending service life. These materials ensure optimal belt tracking and minimize wear on both the pulley and the belt itself. - Repair Solutions

The I-Bond Ezee repair kit is a standout for on-site fixes. This quick and efficient solution minimizes downtime, allowing operations to resume swiftly without compromising belt functionality. - GB-3150 (FR Grade)

Positioned as a direct competitor to Rema Tip Top SC 4000, GB-3150 is a flame-resistant adhesive designed for high-risk environments. It offers superior bonding strength and safety, making it an excellent choice where fire hazards are a concern. This product underscores Oliver Rubber’s ability to match and even exceed industry standards set by renowned solutions like Rema Tip Top SC 4000 Glue.

Why Rema Tip Top SC 4000 Glue Matters

Rema Tip Top SC 4000 Glue is widely recognized as a premium adhesive in the conveyor belt maintenance industry. Known for its exceptional bonding strength and versatility, it sets a high bar for cold vulcanizing solutions. It’s particularly valued for its ability to adhere to a variety of surfaces, including rubber, metal, and fabric, while maintaining durability under harsh conditions. However, Oliver Rubber’s GB-3150 proves that alternatives can deliver comparable performance, especially with added features like flame resistance, catering to specialized needs.

Oliver Rubber’s Commitment to Innovation

What sets Oliver Rubber apart is its dedication to evolving with industry demands. By offering products that rival established names like Rema Tip Top SC 4000, the company demonstrates its focus on quality, safety, and efficiency. Their solutions are not just about fixing belts—they’re about enhancing operational uptime and reducing long-term costs for businesses.

Conclusion

For over 35 years, Oliver Rubber Industries LLP has been a reliable partner in conveyor belt maintenance, delivering a product range that meets diverse industrial needs. From the versatile OM-2000 adhesive to the flame-resistant GB-3150, their offerings provide robust alternatives to industry giants like Rema Tip Top SC 4000. Whether you’re splicing belts, repairing tears, or upgrading pulleys, Oliver Rubber has the tools to keep your conveyor systems running smoothly. In a competitive market, their blend of innovation and reliability ensures they remain a top choice for professionals worldwide.

Leave a Reply