In industries and municipal water systems where space, efficiency, and budget matter, wafer type butterfly valves have become a go-to solution. Compact, reliable, and easy to install, they offer a simple yet powerful way to control flow in pipelines carrying water, chemicals, air, or gas.

In this blog, we’ll break down everything you need to know about wafer type butterfly valves, their working principle, features, and applications. We’ll also explain how they compare to other valves like sluice valves, air valves, and pressure reducing valves.

🔧 What Is a Wafer Type Butterfly Valve?

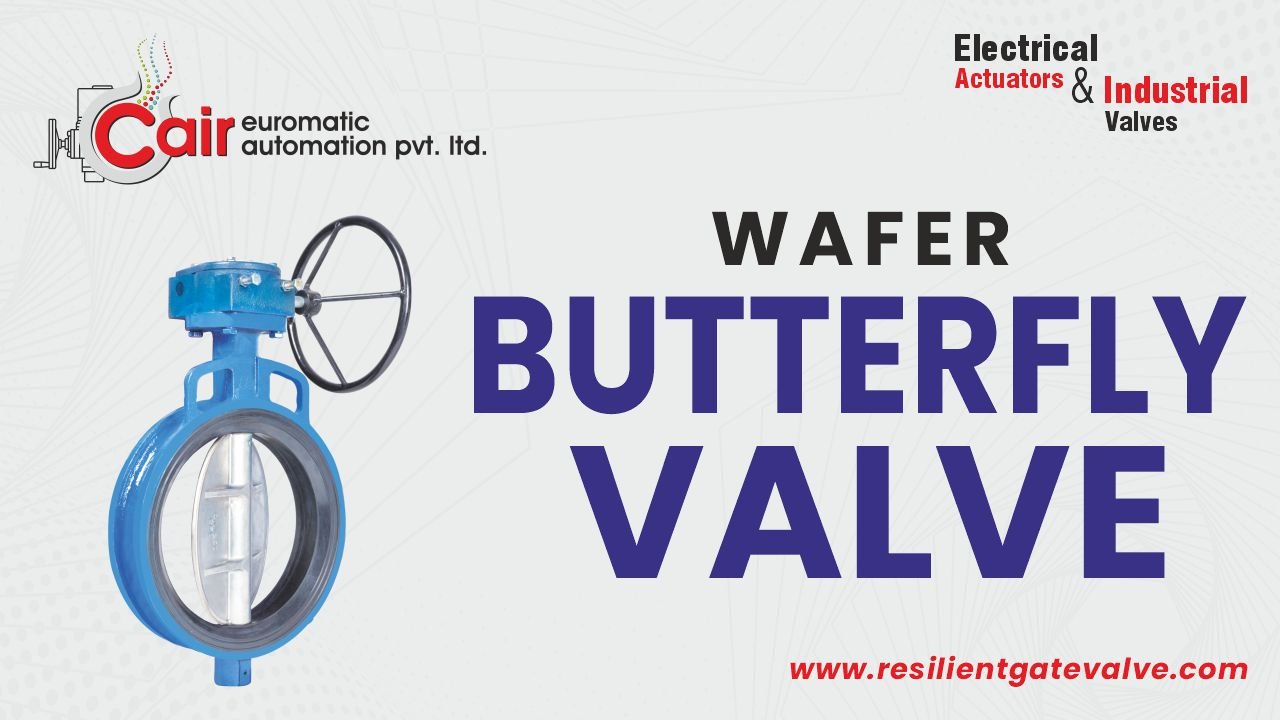

A wafer type butterfly valve is a quarter-turn valve designed to regulate or isolate flow. The valve consists of a metal disc (the “butterfly”) mounted on a rotating shaft. When the handle or actuator turns the shaft 90 degrees, the disc opens or closes the valve to control the fluid flow.

The “wafer” design refers to how the valve is mounted. It is sandwiched between two pipe flanges, making it more compact and lightweight than other flanged valve types.

✅ Key Features of Wafer Type Butterfly Valves

Wafer butterfly valves are widely used due to their cost-efficiency and space-saving design. Below are the standout features that make them popular:

1. Slim Profile & Lightweight

Wafer valves are compact, making them ideal for tight spaces and easy installation. Their lightweight design also reduces load on the piping system.

2. Quick Operation

These valves can be operated manually or automatically and require only a quarter-turn to fully open or close, saving time and effort.

3. Leak-Proof Sealing

Modern wafer butterfly valves come with resilient elastomer seats that provide a bubble-tight seal, even in low-pressure systems.

4. Corrosion Resistance

Valves from reliable manufacturers like resilientgatevalve are coated with epoxy or powder coatings, which help prevent corrosion and ensure longer service life.

5. Low Maintenance

Due to fewer moving parts, wafer butterfly valves require minimal servicing and have a longer operational lifespan.

🛠 Where Are Wafer Type Butterfly Valves Used?

These valves are used across various sectors due to their adaptability. Common applications include:

- 🚰 Municipal Water Supply Systems

- 🏭 Industrial Flow Control (chemicals, oils, gas)

- 🚜 Irrigation Systems

- 🔥 Fire Fighting Networks

- 💧 Sewage & Wastewater Management

- 🌾 Agricultural Water Lines

For municipal projects, engineers often prefer resilient seated sluice valves and wafer butterfly valves together for different pressure zones and flow control.

🆚 Wafer Butterfly Valve vs. Other Flow Control Valves

To choose the right valve for your project, it’s important to understand how wafer type butterfly valves compare with other types:

🔹 Resilient Seated Sluice Valve

These are gate-type valves that provide full bore flow and tight shut-off. They are better for on-off applications in underground water systems.

Use When: You need full flow or zero obstruction.

🔹 Metal Seated Sluice Valve

Ideal for dirty water or high-temperature fluids, where rubber seats may wear out. These valves are heavy-duty but not suitable for tight spaces.

Use When: You have high-pressure, abrasive fluids.

🔹 Air Valves Single and Double

Not used for stopping water, but for removing trapped air in the line. They ensure efficient flow and prevent water hammer.

Use When: You need air release at pipeline high points.

🔹 Non Return Valve (NRV)

Also called check valves, NRVs allow flow in one direction and prevent backflow. Often installed downstream of pumps.

Use When: You need to prevent reverse flow.

🔹 Pressure Reducing Valve

These valves reduce incoming high pressure to a safe level. Ideal for urban water supply or drip irrigation.

Use When: You need controlled pressure zones.

In Summary:

For compact spaces and quick shut-off, wafer butterfly valves are best. But for buried lines or flow regulation, sluice valves or PRVs may be more suitable.

🏭 Why Buy from resilientgatevalve?

We at resilientgatevalve take pride in being one of India’s leading manufacturers of wafer type butterfly valves, offering:

- ✅ AWWA-compliant designs

- ✅ Wafer, Lug, and Double Flanged butterfly valves

- ✅ Resilient seat & metal disc options

- ✅ Manual, gearbox, or actuator operation

- ✅ Sizes ranging from 50mm to 1200mm

Our product range also includes:

- Resilient Seated Sluice Valve Manufacturer solutions

- Metal Seated Sluice Valve for heavy-duty applications

- Air Valves (Single & Double)

- Non Return Valve

- Pressure Reducing Valve systems

All our valves are hydro-tested, corrosion-protected, and backed by expert technical support. We serve clients across India with fast delivery and reliable after-sales service.

📏 How to Select the Right Wafer Butterfly Valve?

When choosing a wafer type butterfly valve, consider:

- 🔍 Application Type: Water, air, chemical, or slurry

- 🔧 Operating Pressure & Temperature

- ⚙️ Operation Type: Manual, electric, or pneumatic

- 📏 Pipe Size & Compatibility

- 💧 Seal Material: EPDM for water, NBR for oil, PTFE for chemicals

- 🏷 Standards Compliance: AWWA, IS, or ISO standards

At resilientgatevalve, our team helps you select the right valve for your specific needs — ensuring long-term performance and safety.

📝 Conclusion

Wafer type butterfly valves are a smart choice for anyone looking for compact, cost-effective, and easy-to-use flow control valves. Whether it’s a municipal water project, an industrial pipeline, or an agricultural system — these valves deliver reliable performance with minimal maintenance.

Leave a Reply